Robot Vision Integration

Motion Controls Robotics can integrate robotic vision into your system by using a variety of tools available on the market including 2D and 3D vision to; eliminate defects, automate production, verify assembly and track parts.

Motion Controls Robotics uses iRVision, DVT and Cognex vision products in its vision systems to solve customer challenges.

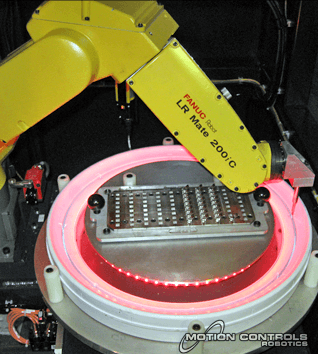

FANUC irVision

The FANUC iRVision system is a ready-to-use robotic vision package available on all new FANUC robots, requiring only a camera and cable – no additional processing hardware. It has a 2D robot guidance tool to accomplish part location, error proofing, and other operations that normally require special sensors or custom fixtures. For robotic vision processes that exceed the capability of 2D vision systems, FANUC Robotics offers an integrated 3D vision system.

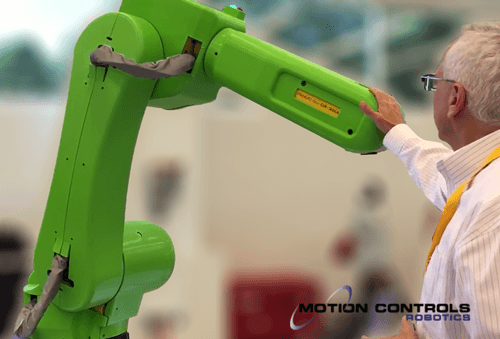

Force Sensing

The new FS-10iA, FS-30 and FS-60 force sensors are an ideal solution to automate part assembly, or to test products requiring delicate force sensing. The devices provide 3D assembly six degrees of freedom. The seamless integration of a six-degrees-of-freedom force sensor results in an intelligent robot that can “feel,” enabling the most demanding mechanical assembly and material removal operations. Material removal applications include; polishing, cutting, grinding, deburring and deflashing.

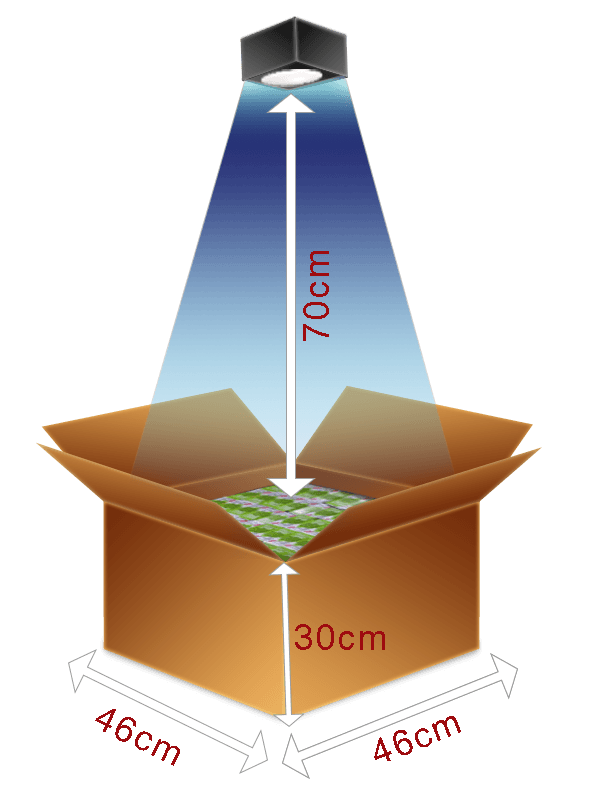

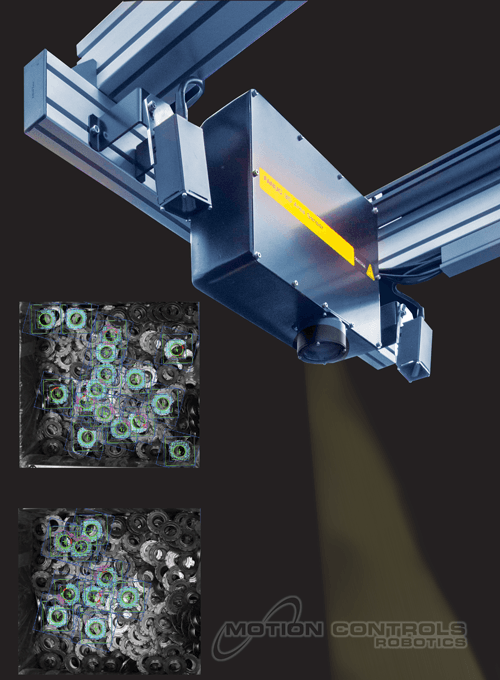

3D Area Scanner

The 3D Area Scanner (3DAS) plots a vast amount of X, Y, and Z points. The image created from this scan of X, Y, and Z points is a 3D map of the product.

The 3DAS can be used for a variety of applications. Robotic palletizing and depalletizing for perfecting pallet stabilization. Then for when pallets come into a distribution center and have jumbled packages the 3DAS can be used to find and pick the correct packages.

The 3DAS has raised the bar for bin picking capabilities. The 3DAS is available in two models for small or larger cell sizes and can be setup using the iPendant.

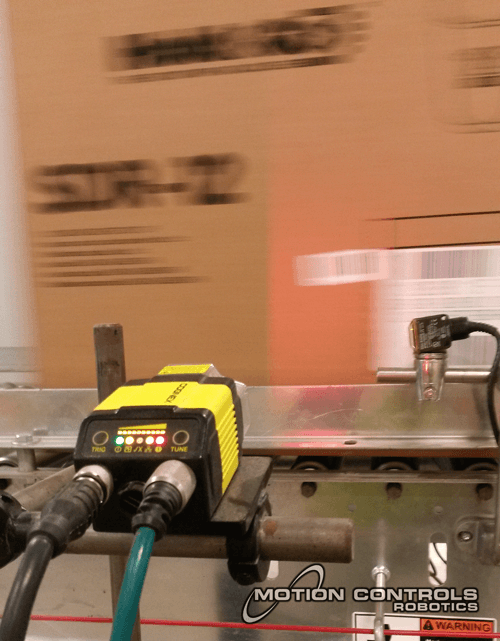

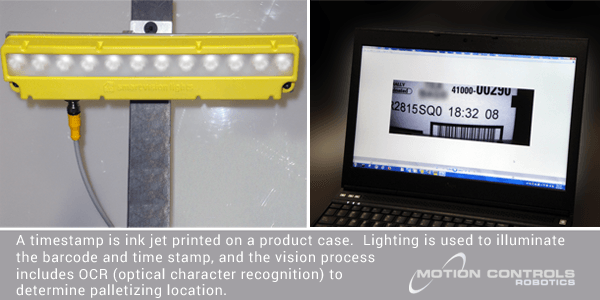

Integrated Barcode Readers for Case Counting

Motion Controls Robotics offers a solution to case tracking challenges. One or more conveyor mounted Cognex barcode scanners work with MCRI supplied case counting software to scan the barcode applied to or printed on each case as it passes by. The information is saved in a CIM file. CIM files allow multiple devices to speak to each other and use the Extensible Markup Language (XML) schema to record data that can be read and used by various ERP (Enterprise Resource Planning) systems.

Features & Benefits

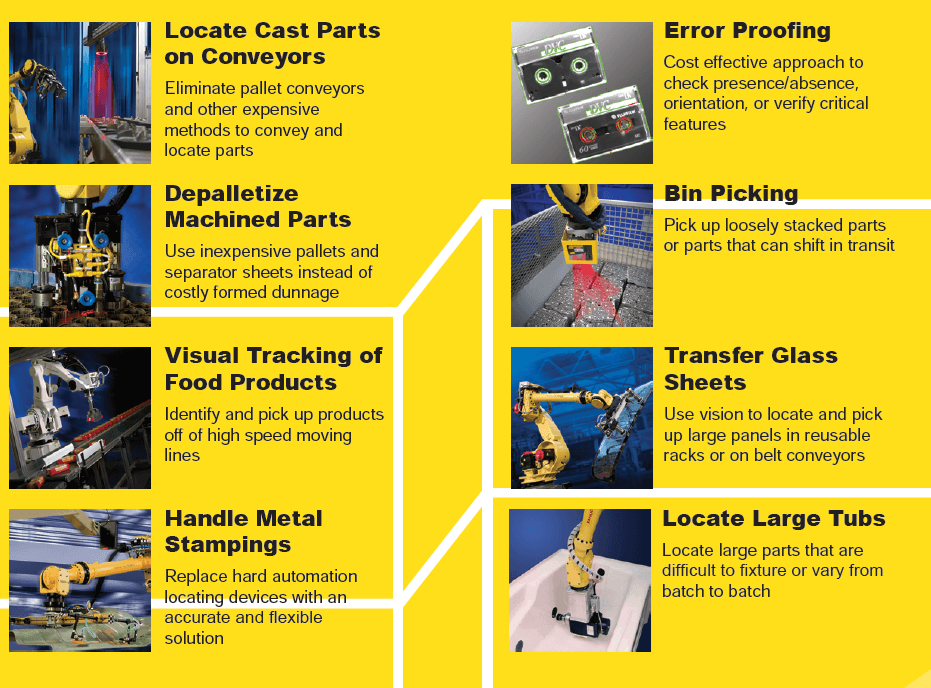

- Can integrate a variety of vision systems, including iRVision, the first on-board robotic vision system, as well as V500, visLOC, Cognex and DVT

- Integrated robot vision system executes the vision process from the main robot CPU and eliminates costly additional hardware and communication delays

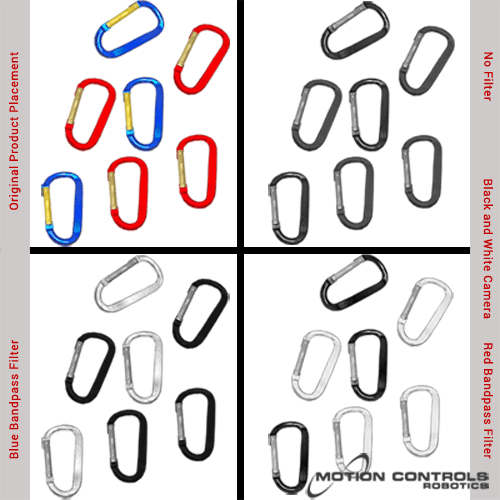

- Robust set of vision algorithms with unique capabilities to emphasize critical features and dynamically mask areas to ignore

- Lighting variations handled with automatic exposure adjustment

- 2D and 3D vision capabilities can be integrated into systems

- Locate parts on conveyors

- De-palletize machined parts

- Visual tracking of products to identify and pick product from high speed moving lines

- Replace inflexible hard automation and tooling

- Conduct error proofing to verify product is assembled correctly

- Transfer sheets of glass or other parts by using vision to locate and pick up panels

- Locate large, difficult to fixture parts or products that vary from batch to batch