Automated Vehicle Options

Click image to learn more

Aspect |

Transfer Carts |

Autonomous Mobile Robots (AMR) |

Automated Guided Vehicles (AGV) |

| Comparing Each Option | |||

| Control Method | Manual or Semi-Automatic | Fully Autonomous | Semi to Fully automatic |

| Navigation | Track installed on the floor | Natural feature navigation | Magnetic track or Natural feature navigation |

| Flexibility | Low | High | Moderate to High |

| Payload Capacity | Up to 3k lbs | Up to 3k lbs | Various models for various applications up to 10k lbs |

| Speed | Low | Moderate to High | Low to Moderate |

| Obstacle Avoidance | Tracking Setup to have no obstacles - fenced systems | Automatic - 360 sensors | Automatic - 360 Sensors |

| Infrastructure Requirements | Minimal | Moderate | Moderate to High |

| Travel Distance | Short tracked movement from one station to another | Variety of distance options | Magnetic tape setup would be a predefined distance/Natural Feature Navigation would allow for more flexibility like the AMR |

| Safety Features | Integrated with a robot system and fencing | 360 Safety Sensors - speed slows and stops | 360 Safety Sensors - speed slows and stops |

| Cost | Lower upfront cost | Moderate upfront cost | Higher upfront cost |

| Industry Applications | Pallet Transport | Pallet Transport, Warehouse movement | Warehouse movement, Pallet Transport |

| Use Cases | Material transport within a fixed path | Flexible material transport | Material transport within a fixed path or flexible |

For Warehouses and Manufacturing

For warehouses and distribution centers, SmartCart offers a wide range of tuggers, which can tow loads anywhere from 60 pounds to 6,000 pounds (based on a trailer friction factor of 2%). SmartCart also includes options for a single or dual roller conveyor AGC, which is useful for delivering pallets (as large as 60″) to and from roller conveyor systems.

For manufacturing applications, the SmartCart AGC

is a flexible, inexpensive round-the-clock workhorse

for repetitively moving work-in-process (WIP) materials between production and buffering areas.

The SmartCart Model 300CF counterbalanced fork type AGC is perfect for picking up and dropping off pallets from conveyors, stretch wrappers or the floor.

SmartCart Control Options

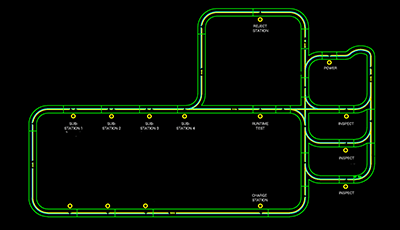

AGC’s can run in a simple loop without upper level computer controls, or a “Cart Management System” (CMS) allows the carts to operate in complex layouts with computer blocking controls and to interface with other in-plant systems. The Windows based CMS cart controller allows the user to reconfigure carts easily, through drop down menus. Modified guidepath layouts and cart functions can be downloaded via Wi-Fi radio signal to the carts in seconds.

An Automatic Guided Cart graphical monitoring screen with simple and intuitive operator interface is available for the CMS controller – providing your operations and maintenance personnel complete control and access to your assembly line. Multiple graphic screens can be easily located anywhere with network access to the CMS.

Contact Motion Controls Robotics, Inc. today to learn more about what you will need to get started on a SmartCart Automatic Guided Cart System. Drive cost savings

to your bottom line, improve your system operation, and provide a more friendly work environment for your most valuable asset – your employees.