In a past MCRI Tech Talk Article, we discussed line tracking options and FANUC’s iRPickTool Software at an overview level. Recently we had a question about using line tracking that came from a Case Packing video we posted on TikTok.

“Very nice application. Can I suggest adding two traps to better align the packages in order to have the robot picking more straight avoiding possible collisions”?

By watching our case packing video alone, without knowing the customer’s situation, this does make sense and brought me to develop this article with the help of one of our programmers. With our 27 years of experience, we have seen jobs where the TikTok commenter is completely correct, but you must know the whole story behind what the customer needs.

To start a deep dive into line tracking options we are going to compare Traditional and 2D Line Tracking with iRVision from FANUC.

Watch video before reading below – the vision system shown was the video posted on TikTok

Line Tracking

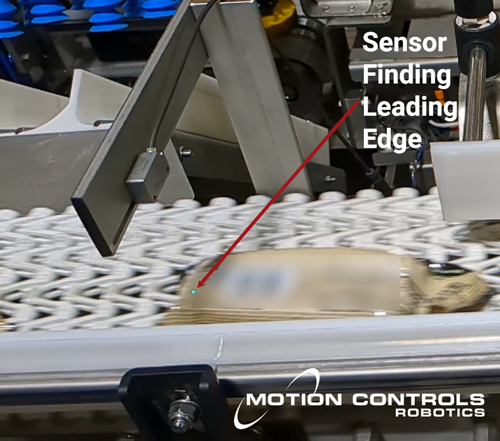

To start, all line tracking needs an encoder. The encoder lets the robot know the speed of the line and the location of the part on the line at the time it is triggered by a sensor or vision. The robot uses this information to gauge when to pick the product. Without knowing the location of the part and the speed of the line, you cannot accurately track a part. At times, lines will need to run at different speeds based on daily throughput changes. So, this is a need for all systems. This is just the first step to starting with line tracking. The two types discussed in this article are the basic next steps and in a later article we will dive into 3D tracking.

Traditional Line Tracking

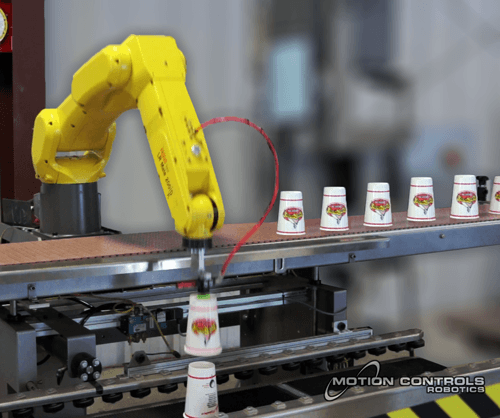

Traditional line tracking uses a sensor trigger without using robot vision. Traditional line tracking cannot figure out the rotation of the part and the robot will not adjust to pick it. In the video above you see traditional tracking is done using fixtures and conveyors to properly line up and space product so the robot can predictably pick the product. The robot is triggered by the sensor when the product passes. The robot will only know the X location (direction of travel of the conveyor). Other sensors can be added to figure out the Y position as well if that is needed.

Sum it up

In traditional line tracking the robot knows the speed of the conveyor and the position of the part at the time it passes the trigger sensor. The robot then picks the product from a specific pick location once it enters the robot’s work envelope. The robot will also discard any product that it cannot pick within its work envelope.

2D Line Tracking with iRVision from FANUC

![]()

2D Visual Line Tracking uses a camera to find the part and send that data (X, Y, sometimes Z, along with R) to the robot so it can adjust to the part accordingly to pick it while it is moving.

For times when fixturing and/or structured part gapping may be too expensive or when you need the flexibility to run multiple products with varied location on the line, robot vision can easily be implemented. FANUC has iRPickTool software that is very easy to setup and get working, usually in less than a day. The addition of vison does not really add much to the total cost of the system, so it can be a good option to keep your choices open.

In the video you can see the 2D line tracking example where products coming down the line are rotated. But in this specific case, they also were running multiple products on this line. Vision can determine which program to run based on the vision process that finds the part.

In addition to line tracking, iRVision can be used to:

- Verify you are packing the correct product

- Pick and place product in the case/tote so labels are sticking out …etc.

- Read and transfer barcode information

For this application, using multiple product types with differing location on the line and part orientation, selecting vision is the best option.

Sum it up

In conclusion 2D line tracking allows the robot to see the product and pick and place the product from and to any desired orientation. Vision can allow for easier changes to the system down the line. The other applications mentioned cannot be done without vision and if you’re going to use vision you might as well use it to line track as well.

Quick comparison chart

Compare |

Line Tracking with iRVision |

Traditional Line Tracking |

| Cost | There is a one-time cost for a camera, encoder, and lighting. Cameras are not a large percentage of the robot cost. | Still need an encoder to track line speed but no camera or lighting is required. Fixtures and part spacing control can be expensive for adding to a current system. |

| Flexibility | Vision is for system flexibility – allowing a robot to make changes based on the product position and orientation. | Perfect for a line that runs one product at a time with consistent spacing. |

| Uses |

The same vision can also:

|

There are no added benefits for traditional line tracking. Parts must be structured in single file and pre-gapped. |

| Rate | The vision system can locate multiple parts, even if they are side by side to help maintain rate but varying part orientation can add to the time to pick. | Fast, consistent picking. The product must be single file and spaced far enough apart to determine the location of the leading edge of each part. |