Adding robotics to improve a process is one of the best ways to keep your facility competitive.

MCRI focusses our robotic expertise on:

- Food & Beverage and Consumer Goods Applications

- Building and Construction

- Films, Papers, and Plastics

- Warehouse Applications

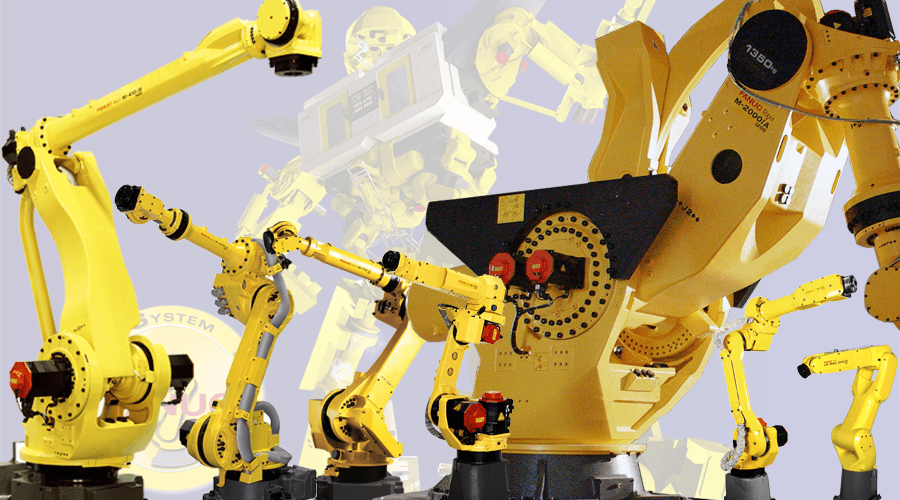

While automotive companies have been leading the way in robot sales, the diversity of companies/industries integrating robots is expanding all the time. This industry diversity will mean the most popular FANUC robots might change. Most currently, the most popular models are the R-1000 and R-2000 series. These robots are common to use on automotive lines.

We develop the custom end of line and material handling solutions that best answer current needs the facility wants to address. In doing so, we may have a different robot mix than than the general robot sales.

So, what robots are the most popular robots facilities are wanting to add to their processes? Motion Controls Robotics has a list of our top 10 most popular FANUC robots, based on the quantity of each robot type we quote for prospective customers. Take a look at the chart below.

Top Ten Popular Robots

Popular Robot Explanations (some similar robots have been combined)

- M410 Series –The M410 series is purpose-designed and built for palletizing. There are a variety of models in this series allowing for payloads up to 700kg. Our two best sellers in this series are the M-410iB/140H and the M-410iC/185.

- R1000/R2000 Series – The R1000/R2000 series of robots are extremely flexible, high speed robots in the medium payload class. While these robots were originally designed for applications in the automotive industry, their versatility makes them relevant in many applications. Here at MCRI we select this robot for general material handling and palletizing.

- CRX – FANUC Cobot Models – Collaborative robot use is growing as integrators and companies are coming up with new ways to integrate these robots. The IFR – Recognized Collaborative Robots as a Top Trend for 2024. According to IFR, “Collaborative robot applications offer a new tool for human workers, relieving and supporting them. They can assist with tasks that require heavy lifting, repetitive motions, or work in dangerous environments.”

- M10 Series/M20 Series – The M10/M20 series has the latest in intelligent technologies allowing for easy integration and a payload limit of 35kg.

- LRMate Series – – LRMates are fun to work with because they have so much flexibility in function. This lighter payload robot series is commonly selected for picking and case packing applications. The LRMate series has a variety of options in the food grade model for picking and packing food items. LR Mates are also fast with up to 85 robot cycles per minute (CPM).

- M710 Series –The M710 series is great for modular, compact applications such as case packing and palletizing cells, part pick and place, bin picking, furnace loading/unloading, and other press tending applications. This robot’s standard model has a high ingress protection (IP) rating, so it is often selected for dirty work.

- M900 Series – The M900 series of six-axis robots feature the best joint speeds, repeatability, and accuracy to suit a variety of heavy material handling applications. This series commonly used for press tending applications.

- M2000 Series – – Our newest robot to join the list is the heavy weight champion weighing in at up to 2300kg load capacity including end of arm tool. MCRI uses this large payload robot mainly for roll handling applications. In these applications a product comes in large, heavy rolls and needs to be moved from one station to another.

Learn more about each robot by clicking the robot’s series name. If you need more information contact MCRI through the new robot request form.