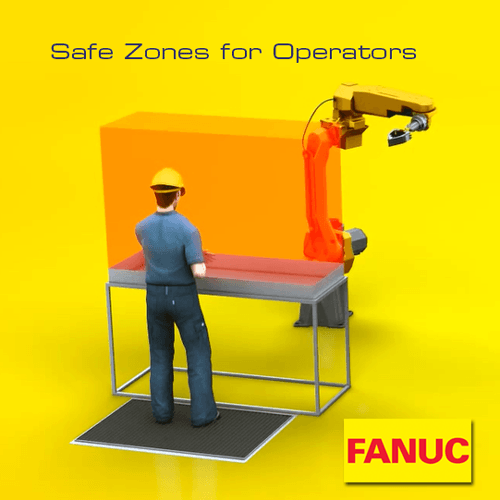

Resetting a Dual Check Safety DCS Alarm

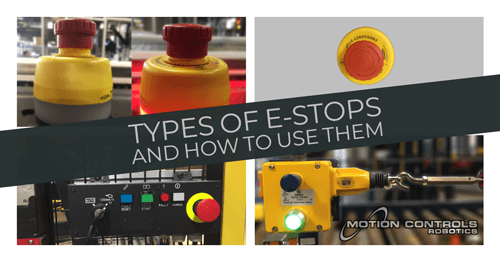

Robot systems include a variety of equipment to keep operators/people safe around an active robot cell. Some of these physical safety devices include: EMERGENCY STOP buttons Safety fences, barriers, or…

Read Article