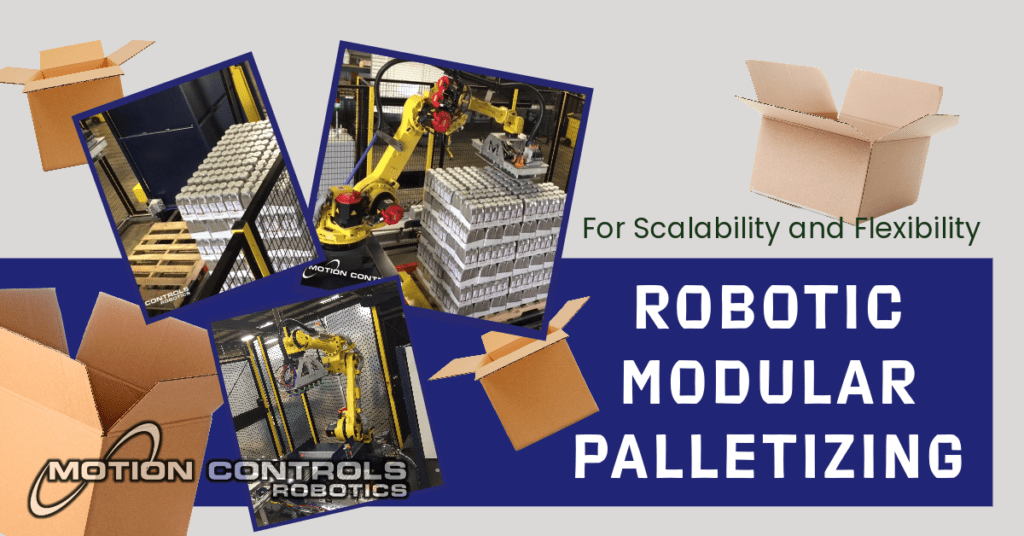

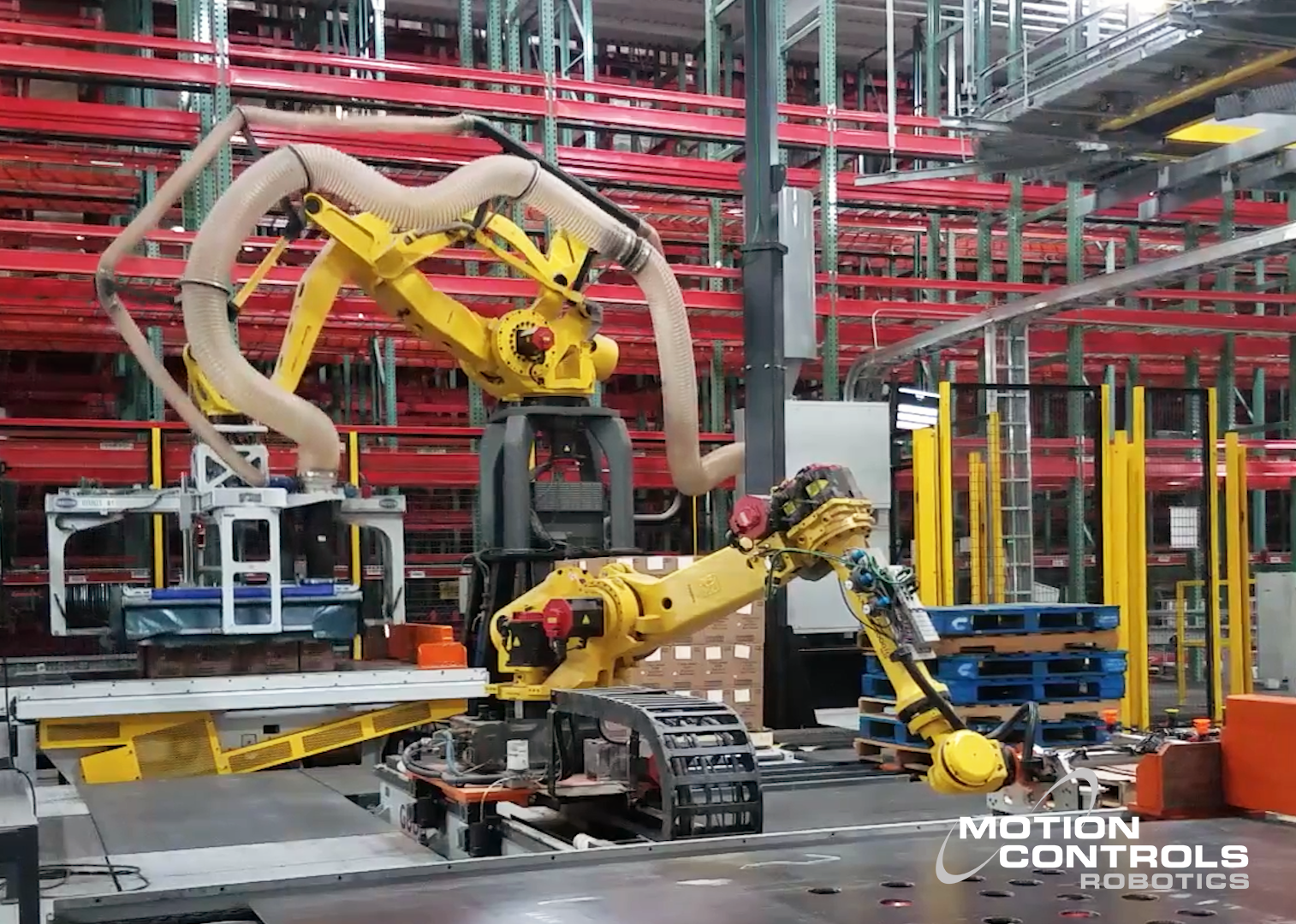

From case palletizing to bags, rolls, slit rolls on end, mixed case load palletizing as well as other challenging palletizing requirements, Motion Controls Robotics has successfully handled it. Motion Controls Robotics develops robotic palletizing system that are highly reliable, flexible to handle various configurations and able to handle process adjustments on the fly. Put our experience to work for you to increase your throughput and reduce your costs.

From case palletizing to bags, rolls, slit rolls on end, mixed case load palletizing as well as other challenging palletizing requirements, Motion Controls Robotics has successfully handled it. Motion Controls Robotics develops robotic palletizing system that are highly reliable, flexible to handle various configurations and able to handle process adjustments on the fly. Put our experience to work for you to increase your throughput and reduce your costs.

Motion Controls Robotics, Inc robotic palletizing solutions may include:

- Robotic simulation

- Robotic vision systems

- Single or random pallet racks or dispensers

- Slip sheet rack

- Separate slip sheet dispenser

- Upstream processing to prepare product for palletizing

- Vacuum, Servo Adjustable, or gripper style end of arm tool

- Case conveyor or SmartCart Automatic Guided Carts (AGCs) to move product to the palletizing cell

- Finished pallet takeaway with pallet conveyor or SmartCart AGCs

Select the Type of Palletizing Operation You Need

Palletizing Robots

Click on any of the robots below to learn more

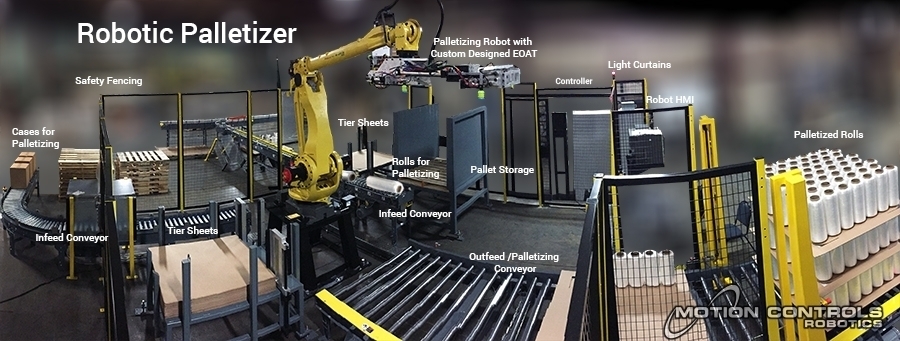

Layout of a Robotic Palletizer – M- Case2Cube

The Motion Controls Robotics M-Case2Cube System is designed around a best in class, high-speed Fanuc M410iB/140H robot. When equipped with the standard end of arm tool, it can handle cases in excess of 35 lbs at rates up to 32 cases per minute. The M-Case2Cube is pre-engineered to keep cost and lead times down. Additionally, its compact size takes up the same or less space than a traditional palletizer.

Palletizing – Base System:

| Fanuc M410iB/140H | Vacuum zone EOAT for picking up cases |

| 10” HMI w/ color touchscreen | Pallet picking jaws |

| Pallet build station | Exit conveyor |

| Infeed conveyor | Pallet rack |

| Safety enclosure |