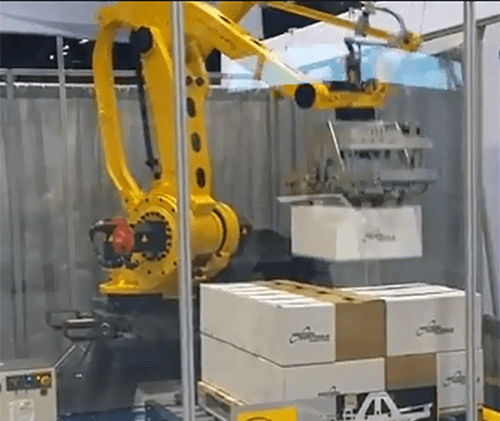

Flavored Palletizing – Mixed Loads

Motion Controls Robotics develops flavored palletizing systems that automate mixed unit loads. Motion Controls Robotics uses FANUC Robotics’ Random Order PalletTool software to provide an efficient method of setting up, controlling and monitoring mixed load palletizing applications. Distribution and order fulfillment centers need systems that allow products to be individually picked and manually palletized to maximize pallet load density. Non automated mixed palletizing applications are labor intensive, with little control on the pallet density or stability. With this software, a robotic palletizing system can be set up to monitor a random sequence of cases with random sizes to build an efficient pallet pattern with high density and stability.

The system is designed to pick cases from an infeed buffering zone and place them onto a corresponding pallet. Prior to entering the infeed buffer area, the cases are passed through a peripheral identification device to obtain case characteristics (size and weight). These characteristics can be retrieved from a part database or direct dimensioning system. The infeed buffer area provides a greater selection of units when determining pallet positions for a desirable, stable and dense load.

Features and Benefits

- Reduces vendor noncompliance cost recovery charge backs associated with improved shipping accuracy of customer orders.

- Reduces manual palletizing labor costs.

Flexible:

- Can palletize two orders simultaneously from separate infeed conveyors.

- Buffering zones can range from one to eight cases per infeed.

- Four pallet locations are supported. One order can be palletized to multiple pallets if required.

- Flexible tooling supports a wide range of case dimensions. Standard tooling developed to support case range of 6-24 inches.

- Supports independent case soldiering to help increase pallet density and stability.

- Interface to standard bar code readers or identification devices.

Palletizing System:

- Set up communication to customer’s part database and order database system.

- Operator production control:start/stop production, monitor current cell status, change orders, error recovery, index pallets.