FANUC robots have been engineered and designed to perform flawlessly and last for many years. The spotlight is now on the integrator to design flexible and unique end of arm tools (EOAT) that meet the user’s varied needs. MCRI has discovered the answer to this is a Servo Adjustable End of Arm Tool. One area of automation that Motion Controls Robotics specializes in is palletizing. It is a priority to give customers the ability to handle various configurations, make process adjustments on the fly, and start/stop palletizing operations easily.

Experience designing a variety of palletizing systems has lead our engineers to develop the new Servo Adjustable End of Arm Tool. This EOAT uses vacuum grippers that can dynamically adjust to a variety of case sizes and pallet patterns.

Below are the 5 biggest challenges the new Servo Adjustable End of Arm Tool addresses:

Customer Challenge #1

- We pack our product in boxes with glued, split top flaps. Using these boxes saves a lot of money, but in our experience, vacuum grippers will not reliably pick-up these types of boxes.

- MCRI Solution: With almost infinite flexibility in gripper positioning, cups can be made to always locate on the end of the box top.

Customer Challenge #2

- Each day we run a different case size and pallet pattern on the line. I need a palletizing solution that can quickly adjust to this change.

- MCRI Solution: With the Servo Adjustable EOAT, you never have to worry about changes in case size. This gripper can handle a wide range of product or case sizes and the continuously adjustable vacuum cups can be programmed and then easily selected by the operator. And, the operator can easily recall a specific pattern from a nearly unlimited number of palletizing patterns stored in the robot controller.

Customer Challenge #3

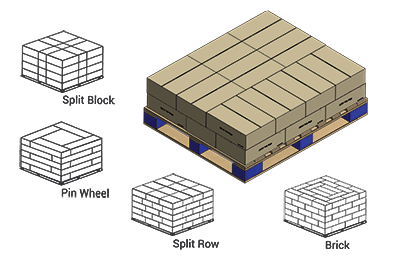

- I need to have the ability to make a variety of pallet patterns with different case sizes arranged on a pallet.

- MCRI Solution: Vacuum cups dynamically locate based on variable case sizes, so the Servo Adjustable EOAT can pick up boxes from multiple lines and allows selective picking and dropping of one or multiple cases, for complex palletizing patterns. This can include in/out label or other pallet specific case orientations.

Customer Challenge #4

- Using a foam and vacuum area gripper I get varied results and boxes are sometimes dropped.

- MCRI Solution: The Servo Adjustable EOAT is not only more flexible than a foam gripper but eliminates check valve and sealing foam issues, and foam degradation issues associated with that type of gripper.

Customer Challenge #5

- We have four incoming conveyors with different box sizes. Will I be able to use one robot to separate these onto four different pallets all with different pallet patterns?

- MCRI Solution: The programing for the Servo Adjustable EOAT can be programmed to know what type of box is coming off the conveyor, the pallet pattern used, and the proper pallet to use for palletizing the cases.

If you would like to learn more about implementing a Servo Adjustable End of Arm Tool into your process, Contact MCRI.