This is the last article covering the main types of grippers used in robotic applications. Remember that most times a custom designed EOAT will include multiple types of grippers to provide flexibility in the process.

Also in our gripper series:

Robotic End Effectors, Pneumatic or Servo Grippers, and other End of Arm Tooling (EOAT) are like the robot’s hands. They perform functions like material handling, pick & place, and machine loading/unloading.

Airflow/Foam Grippers

Air flow grippers employ a foam pad to lift materials. These types of grippers are very flexible and can be used to pick entire layers of products or variable sized products with the same gripper.

Common characteristics

- “Motor” generated vacuum

- Air flow grippers allow handling of porous materials like foam, fiberglass

- Can lift partial and full layers in palletizing applications

- Controllable air flow for different product handling

- Require correct foam pad density based on product handled

Air flow or foam grippers are great for products that are porous such as wood, papers, and fabrics. This type of gripper is popular within the consumer goods and food & beverage industry where it can be used to pick and place layers of empty plastic or glass bottles and other containers.

Foam plenums can be combined with venturi vacuum generators to form a special category of grippers that dynamically adjust to the shape of the product being picked. An array of venturi vacuum generators each with special check valve rests on the back side of a foam pad. As the robot places the end of arm tool onto the product to be picked, the check valves retract where the product contacts the foam, and vacuum is created above the product. The other vacuum generators stay shut, reducing the amount of compressed air required for the end of arm tool. While usually more expensive than vacuum cup style Venturi grippers, these are very flexible and do not require any zone programming for the end of arm tool. (see Schmalz or Coval vacuum plenum grippers) This style of gripper can also be supplied with an array of tightly spaced vacuum cups instead of foam, with similar results. While more expensive, the tightly spaced array of vacuum cups combined with the special check valves provides a very flexible gripper face that is more durable than a foam pad.

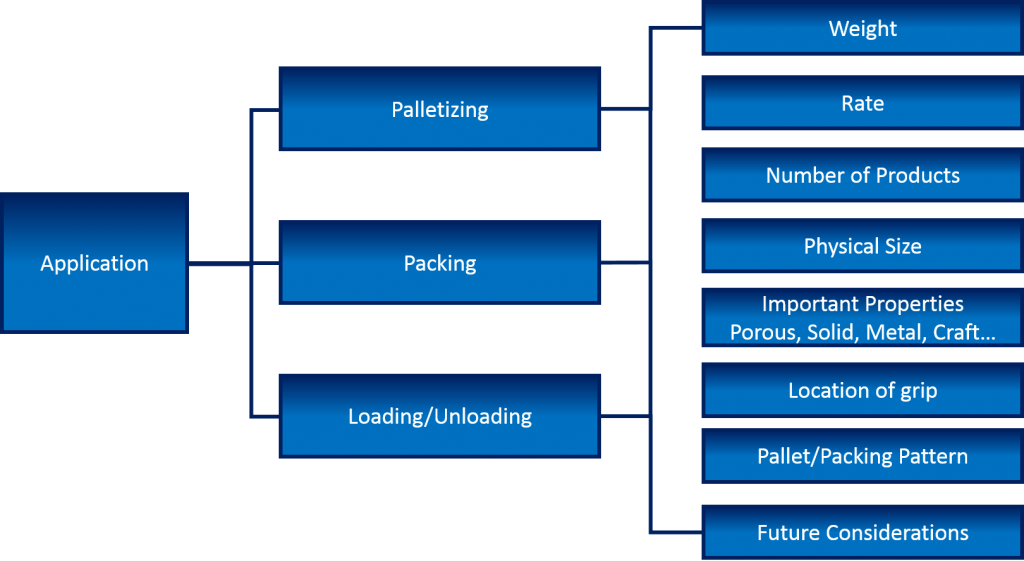

Gripper Selection Chart

As a final addition to our gripper series, we are including an end of arm tool selection chart. This chart contains all the items that come in to play when selecting the best type of EOAT for your application.

If you think that a custom designed multi-gripper with an air flow gripper would help increase the efficiency of your process, contact Motion Controls Robotics for an evaluation. If you currently use an air flow gripper in your robotic system, we would love to see and share your experience. Fill out our contact form and we will share on MCRI’s Facebook page.