The levels of system automation that you implement in your facility can range from single small cells to large interconnected systems. The great thing is the ability to start small and grow when you want to find more automation benefits.

Here are some of the top benefits of automation:

- Reduce your dependency on labor.

- Increase your ability to adapt and scale capacity.

- Increase efficiency and productivity.

- Reduce waste through improved quality and consistency.

- Supply your employees with more engaging jobs.

- Offer a safer working environment.

- Increased your competitive advantage.

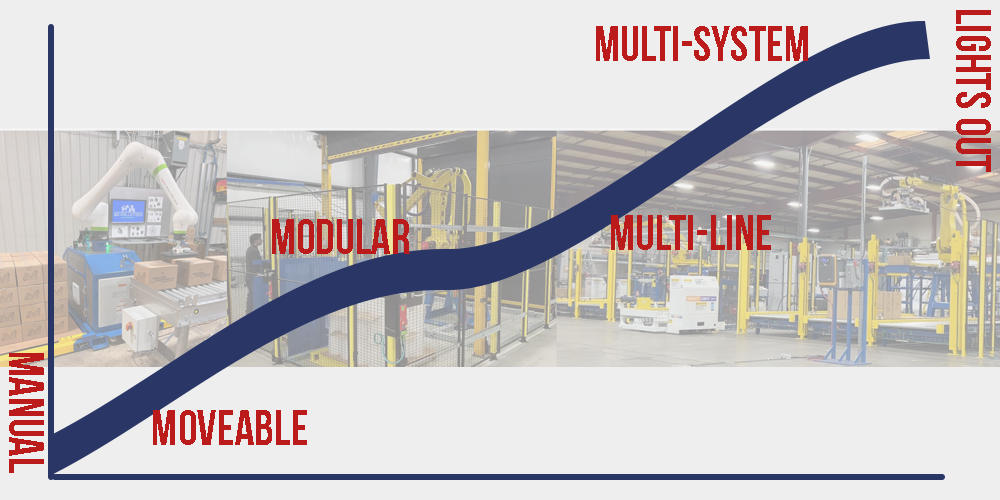

This article is going to breakdown automation levels into 4 types of systems. We call this the The 4-M Robotics Adoption Curve.

Levels of System Automation

- Mobile/Moveable

- Modular

- Multi-line

- Multi-system

Each level of automation offers distinct advantages and presents unique challenges. Manufacturing and warehouse facilities must carefully consider their current needs, future growth expectations, and operational flexibility to choose the most appropriate level of automation. By addressing these factors, companies can effectively implement automation to improve efficiency, reduce costs, and enhance competitiveness in their respective markets.

Mobile or Movable Automation (e.g., BA Palletizer)

This level of automation includes systems that are not permanently installed in a fixed location within the facility. These systems, such as the BA Palletizer, are designed to be easily moved and redeployed to different parts of the production floor as needed. Mobile automation is typically used for tasks like palletizing, labeling, and packaging. The main advantage is their flexibility, as they can be adapted quickly to changes in production requirements without the need for extensive reconfiguration.

🎯 Pros of Moveable Automation:

- Flexibility: These systems can be moved and reconfigured as needed, allowing for easy adaptation to changing production demands.

- Cost-effective: Lower initial investment compared to fixed automation systems, offering a viable option for smaller operations or those new to automation.

Limits:

- Limited Capacity: While flexible, these units might not handle high volumes as efficiently as fixed systems. You may discover moveable automation starts in one area and as capacity increases are moved to a new line. When a facility starts to see limits it is a good idea to evaluate adding more robust systems.

- Dependency on Human Operators: Although automated, they may require manual oversight and intervention for optimal performance.

Moveable Automation Challenges and Solutions:

- Integration: One challenge you may have with a Mobile system is integration. These systems are not designed to be interconnected to your plant system but offer flexibility for changing demands.

- Solution: Implement advanced software that can easily integrate with different technologies and provide real-time data for better coordination. MCRI has an example of this type of software called ImpactIQ.

🚦Levels of System Automation – Moveable Example

Click here > BA Palletizer

🎯Modular Cells

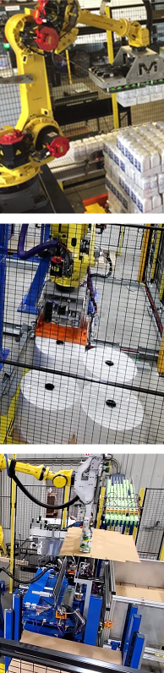

Modular automation cells are compact, self-contained units that perform specific tasks or a series of tasks within the manufacturing process. These cells are designed to be quickly integrated into existing production lines, adding capacity or functionality with minimal disruption. Modular cells can vary in complexity, from simple single-function machines to more complex systems capable of handling multiple operations. Some of the addons to modular cells include (but aren’t limited to): pallet dispensers, case erectors, case packers, labeling, safety doors, AGV/Transfer cart for full pallet handling. The key benefit of modular cells is their scalability, allowing manufacturers to incrementally increase automation in response to growing demand.

Pros of Modular Automation:

- Scalability: Easily expandable; additional modules can be added as needed without disrupting existing operations.

- Rapid Deployment: Quick to get installed and running, minimizing downtime.

Limits:

- Space Requirements: Each module still requires dedicated space within a facility, which may not be available.

- Coordination: Managing multiple autonomous units requires sophisticated coordination systems.

Modular Automation Challenges and Solutions:

- Effective Layout Planning: Designing a floor plan that accommodates modular growth needs to be at the top of your mind when you decide to develop modular automation.

- Solution: Utilize advanced planning software to simulate various layout scenarios and optimize space utilization.

🚦Modular Example

Click here > Modular Palletizer – Dual M-Stack Palletizer or Flexible Packaging – erect, pick, pack, label and palletize

Multi-Line Systems

Multi-Line systems represent a more integrated approach to automation, where multiple production lines or processes are automated in a single compact system. These systems can manage different products or SKUs simultaneously, often within a confined area. This approach maximizes space efficiency and can significantly reduce the movement of materials across the facility. Multi-line systems frequently incorporate advanced technologies such as robotics and Automatic Guided Vehicles (AGVs) to enhance workflow and reduce manual intervention.

Pros of Multi-Line:

- Efficiency in Space Utilization: Consolidates multiple functions into a single area, reducing the footprint.

- Versatility: Capable of handling various SKUs, which enhances the system’s utility across diverse product lines.

Limits:

- Higher Costs: More complex systems are typically more expensive to implement.

Multi-Line Challenges and Solutions:

- Cost Management: Balancing the benefits of multi-line systems with cost and floorspace.

- Solution: Conduct a thorough analysis to determine whether space or cost is more important for future growth.

🚦Multi-Line Example

Click here > 2 Line Bag Palletizer 2 SKUs at one with no cross contamination possible

Multi-System Automation

The most advanced level of automation, multi-system integration, involves automating virtually every aspect of the manufacturing process and linking these automated systems to function as a cohesive unit. This level aims to create a fully automated production environment where different systems communicate with each other and operate with minimal human oversight. This comprehensive integration not only maximizes efficiency and throughput but also significantly reduces the potential for human error and increases production consistency.

Pros of Multi-System:

- Comprehensive Integration: Connects all phases of production, from start to finish, enhancing overall efficiency.

- Near-Lights-Out Operation: Maximizes automation, potentially running with minimal human intervention.

Limits:

- High Initial Investment: The cost of fully integrating an entire manufacturing process can be prohibitive.

- Complex Implementation: Requires extensive planning, time, and expertise to implement.

Multi-System Challenges and Solutions:

- System Complexity and Reliability: Ensuring all components work seamlessly together.

- Solution: Use reliable, field-tested components and engage with experienced integrators who have a track record of building complex systems.

🚦Multi-System Example

Click here > Moving caps from start of process through to stretch wrapper

The next step is to achieve a “lights-out” manufacturing capability, where the facility can run autonomously for extended periods. This may not be feasible for many facilities, but any of the robotic levels above will help you increase efficiency.