Robotic PickPakPal

Case Packing and Palletizing End-of-Line Packing Solution

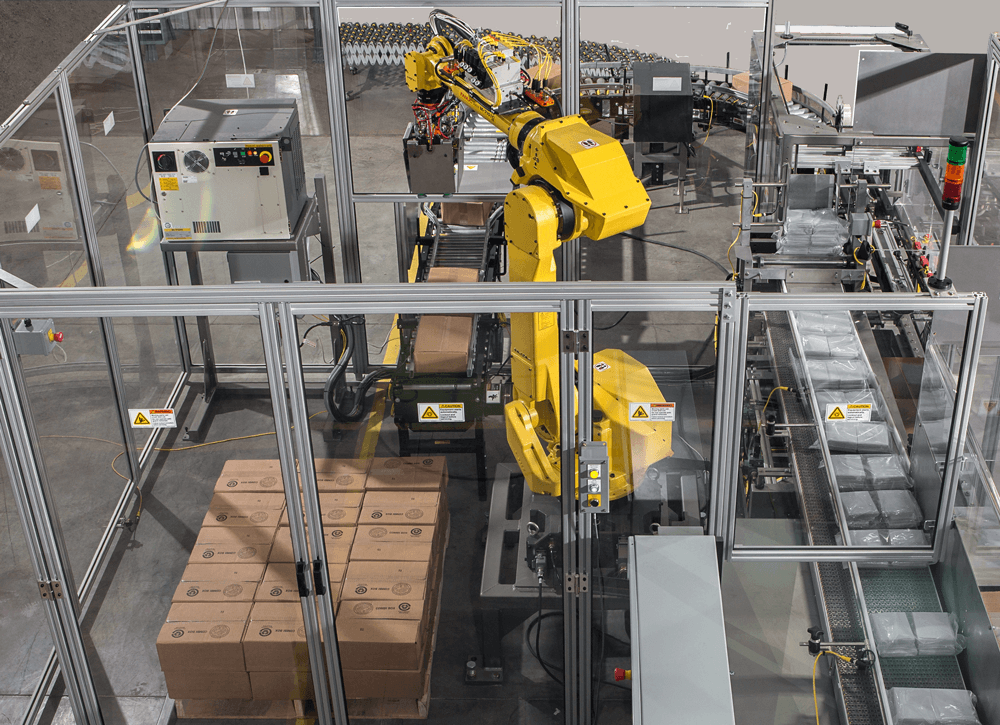

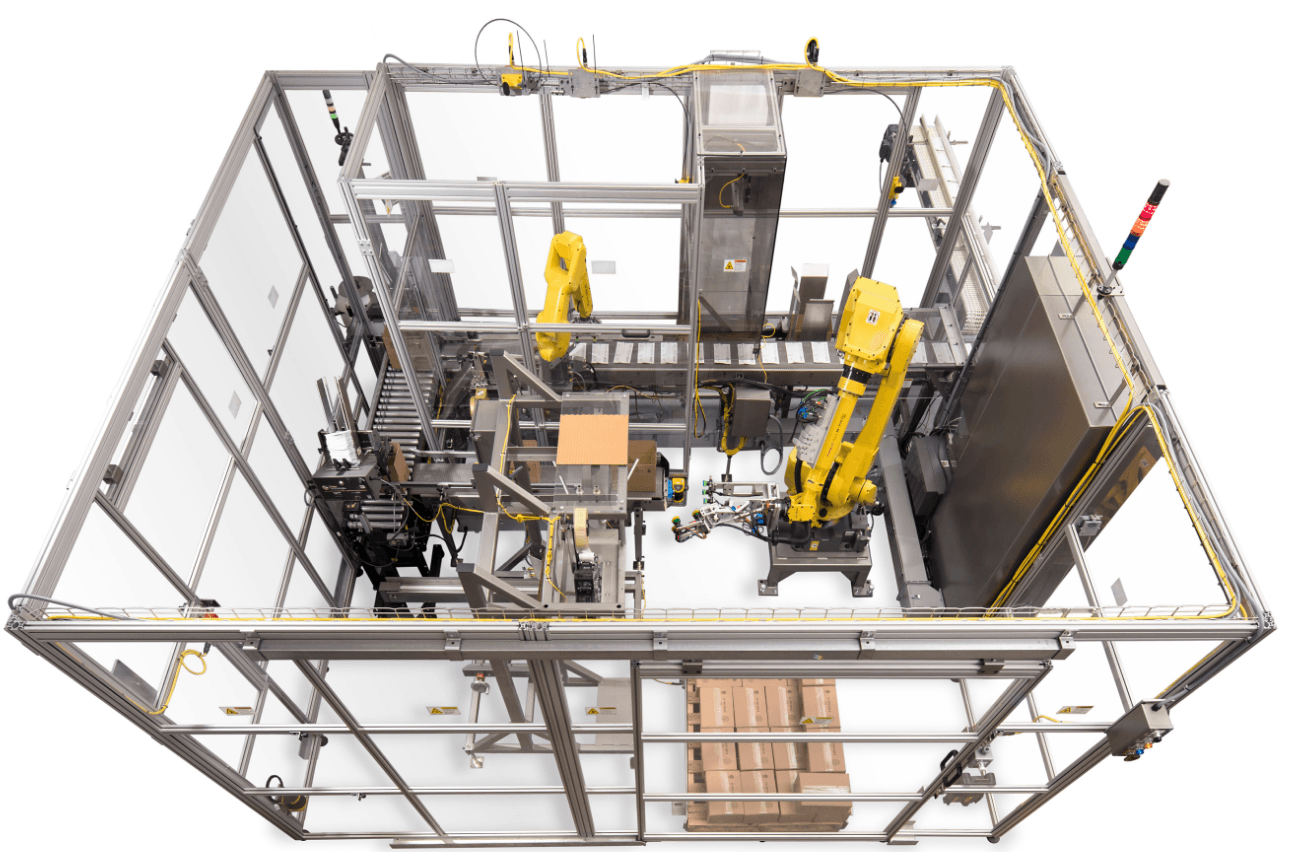

Robotic PickPakPal – Case Packing and Palletizing System

The PickPakPal is a complete robotic system flexible enough to work with a variety of product types, weights, and sizes. The system includes complete design/detail, fabrication, assembly, robot, software, and electrical. We setup the system at our site for runoff approval and then bring to your site for testing and startup.

Description

The PickPakPal Cell is a complete robotic system flexible enough to work with a variety of product types, weights, and sizes.

The PickPakPal Cell utilizes the following stations offering a variety of capabilities:

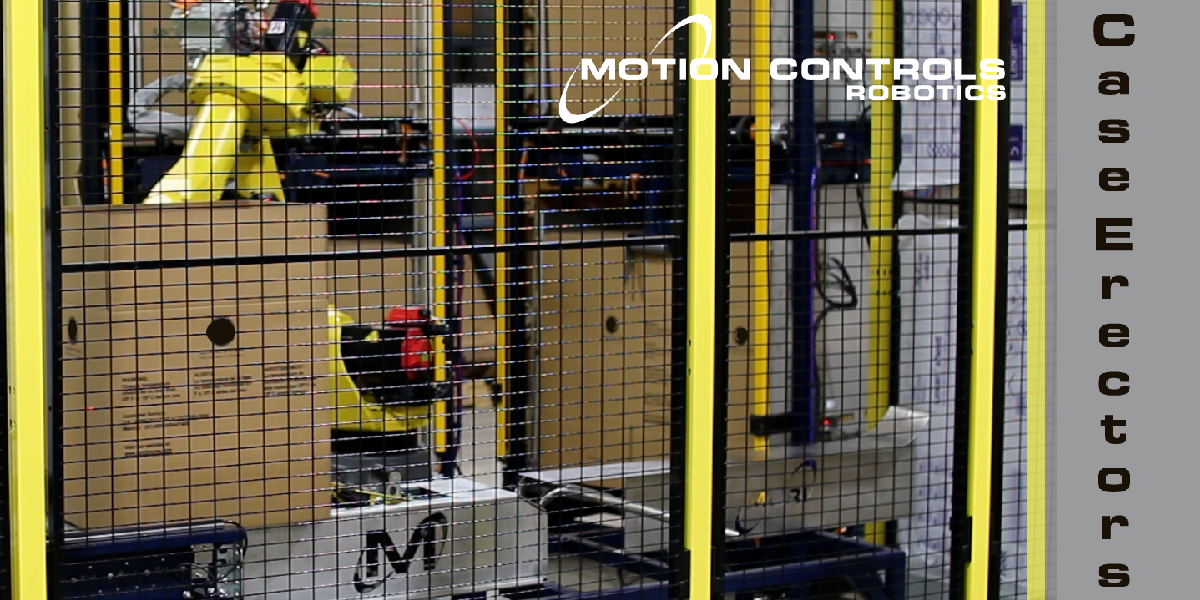

- Automatic Case Erector

- Product Accumulation

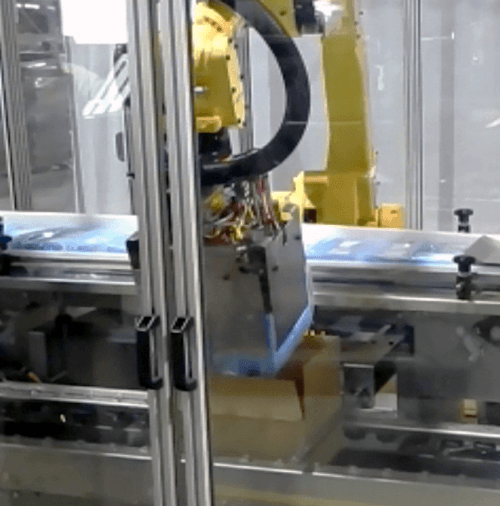

- Case Packing Station

- Product Infeed Conveyor

- Case Sealer (adhesive tape or hot melt glue)

- Case Transfer Conveyor

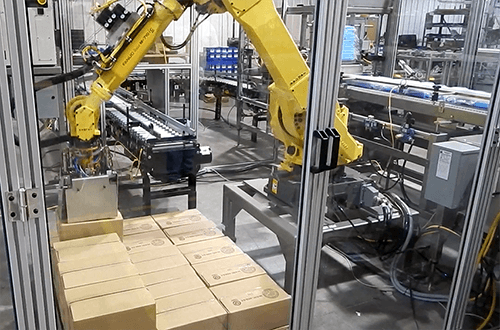

- Case Palletizing Station

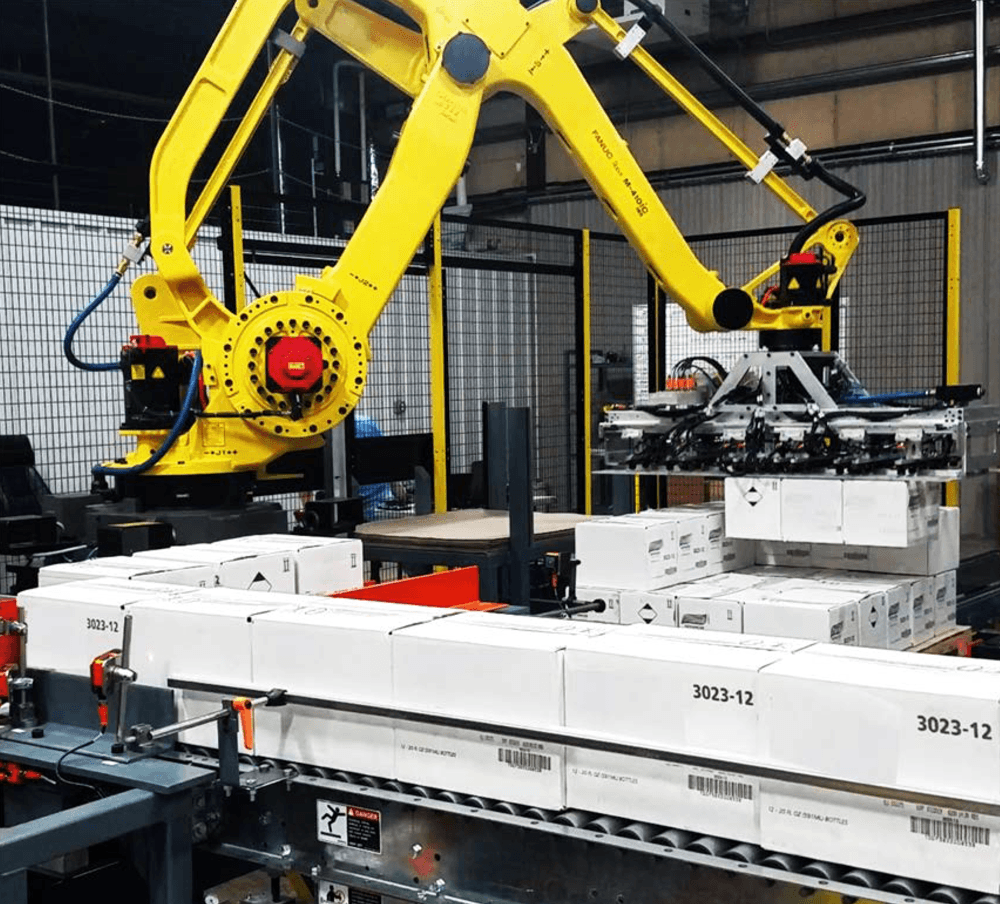

- FANUC M70iC, R1000iC or R2000iC series robots

The Robotic PickPakPal includes:

- 6 axis FANUC robot selected for the application- FANUC M710iC robot

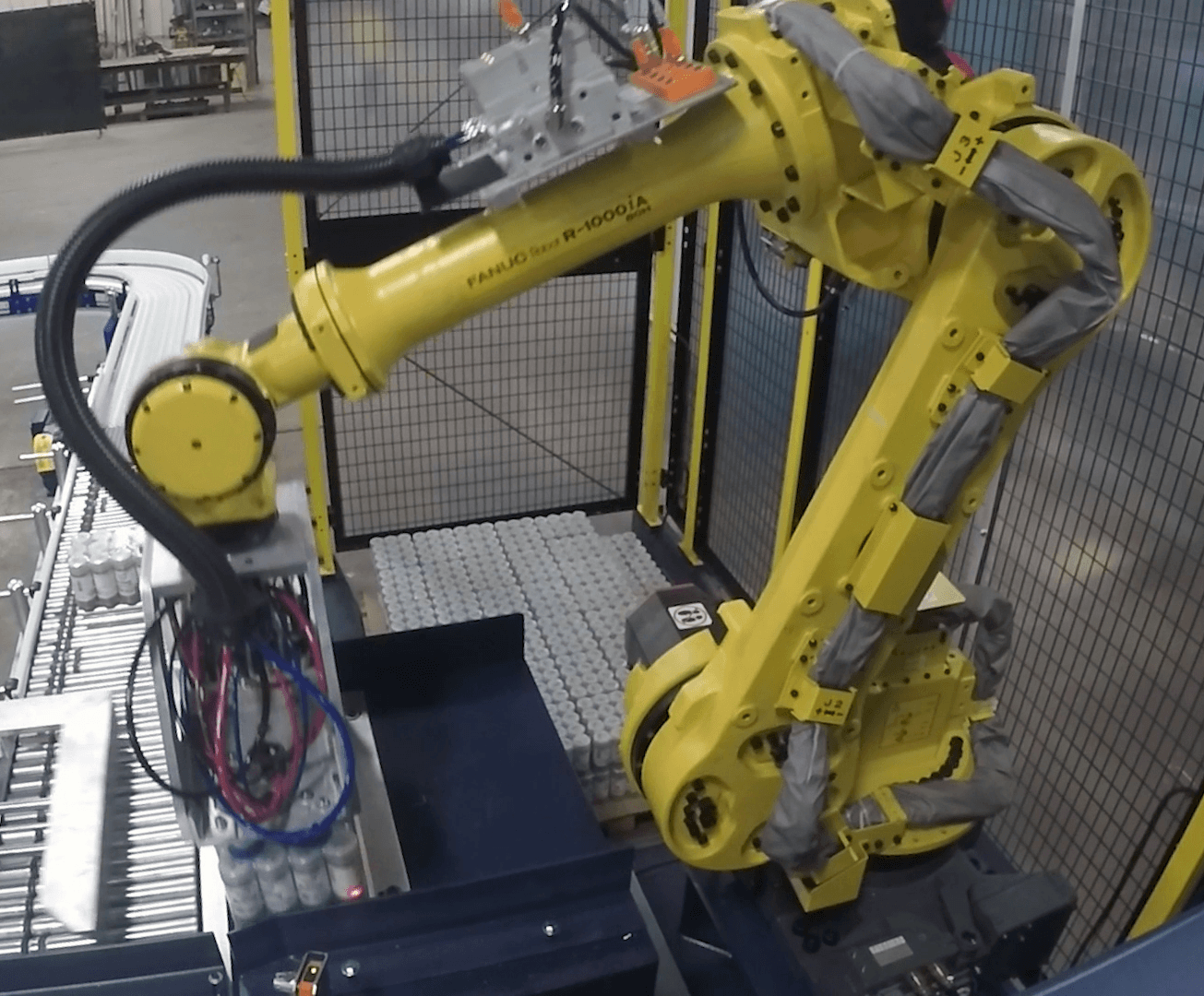

- The high speed and compact FANUC R1000 or larger R2000 robot can also be used in jobs where higher weight and/or longer reach are required.

- Fixed robot base anchored to the floor

- Custom, flexible end of arm tool for dual purpose case packing and palletizing

- Integrated FANUC iRVision system/2D Tracking software (optional per application)

- System wiring and controls

- Operator pendant or optional HMI display for recipe management

- Perimeter guarding with safety interlocks on doors

- Programming for Robot, PLC/PMC, HMI and Vision

- On-site Training and Support

- Compliance with all applicable RIA specified safety standards

- Mechanical and Electrical Engineering including layout of cell system, design, and detail

Additional information

| FANUC Robot | FANUC M710iC or FANUC R1000R2000 |

|---|---|

| Robot Vision | Advances in vision sensor technology and FANUC’s iR Vision allow for inexpensive 100% quality testing, higher pick rates, picking from a moving conveyor belt, identification of part orientation and many other beneficial functions |