Dairy Industry Manufacturing - End of Line Packaging

Motion Controls Robotics’ builds small or large footprint robotic cells specifically designed for plastic jug palletizing.

Leading dairy producers work with us to develop robot palletizing cells for plastic gallon jugs.

Some issues that MCRI robotic systems address:

- employees having to remain in near-zero temperatures

- able to connect to the current flow of the product

- rate and stack quality is improved

- flexibility in stack patterns with the various dollies and trays

- keeping End of Arm Tooling (EOAT) functioning in the cold room temperatures

Robot Palletizes Jugs onto Orbis Trays

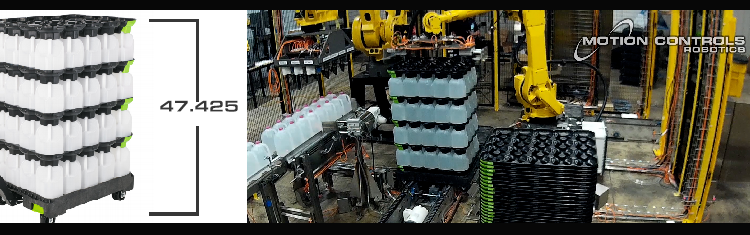

Motion Controls Robotics’ recent integration project shows a small footprint robotic cell designed for plastic jug palletizing. This system features two different FANUC robot models that share the cell and work together to palletize the gallon jugs and move new trays and dollies onto the outfeed conveyor.

Orbis Dolly/Tray

Motion Controls Robotics collaborated with ORBIS Corporation, a leading manufacturer of plastic returnable/reusable products for use in a wide range of material handling applications, to develop the robotic palletizing solution for this customer.

Dollies and trays are washable and returnable.

The primary advantage of the returnable dolly system is realized at the retailer’s site. Retailers are thrilled with the reduction in floor space required for returnable carts, compared to a traditional milk bossy or rack. A stack of empty dollies, with separator trays stacked on top of the dollies, requires a fraction of the floor space in the receiving/storage area of these locations, freeing up valuable floor space for other products.

A large volume retailer can free up a substantial portion of their receiving/shipping area by switching to this design.

Freezer and Cold Room Case Packing/Palletizing/Depalletizing

Robots are widely used in case packing and palletizing applications in freezers or cold rooms to reduce requirements for employees to work in this challenging environment.

End of Arm Tooling

End of arm tool design requires special attention for these applications. Certain materials may degrade and fail when left in freezing temperatures. Frozen goods material handling may also benefit from ceiling mounted, or robots mounted on a floor level or overhead rail for flexibility in removing or adding items to a freezer area.

Ice cream, milk, cheese and other dairy products, meat, frozen RTE (ready to eat) foods and other products produced and warehoused in cold temperatures are great candidates for robotic case packing, palletizing, and depalletizing.