Motion Controls Robotics has a proven ability to manage large projects and will be my first choice going forward.

~ Building Material Company

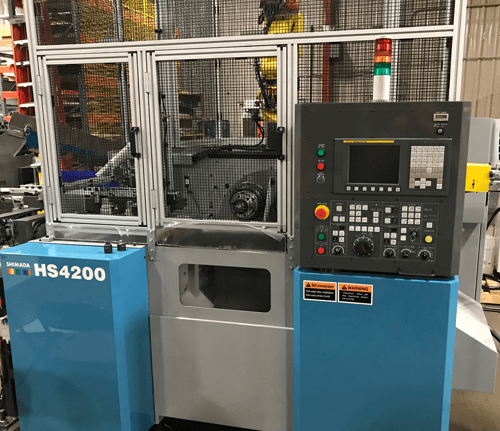

Machine Tending Load/Unload

I have been working with MCRI for many years in automating the loading/unloading of Kitako multi spindle CNC lathes. They are very professional from the quoting process through to the final build, and delivery to our end user. Prior to using MCRI, I had to travel to Japan to have the machines automated by the manufacturer. There were always situations and delays that were made worse by the language barriers and lack of local sources of supplies. It is so much more convenient having everything built in Ohio, and then having MCRI support the equipment. They work as an active partner for my turnkey projects.

I would highly recommend using MCRI for any robotic application, not just machine tending.

Henry Rabinovich

Precision Machine Tools

Plastics and Containers Industry

Motion Controls has proven themselves to be a highly intelligent and capable robotic integrator. Their team invested the appropriate research and talent to ensure that our needs were met from all aspects of safety, delivery, and performance. I would highly recommend them to anyone needing a robotic solution to their process.

Corporate Engineer

Berry Global

Thank you MCRI for the outstanding customer service provided in resolving the issue with our robot. Your response on such short notice was remarkable.

~ Healthcare Industry Customer

The reason I prefer to work with MCRI is because of their technical knowledge and customer service. Their entire team takes pride in the work and is dedicated to providing a system or solution the customer wants. I believe part of the reason their systems run so well in our plant is because of the amount of time dedicated to design and development. I have also been impressed with the flexibility and support when timelines or scope-of-work change during projects. One of my favorite things about MCRI is that it feels like working with a friend instead of another vendor.

Electrical Engineer – Kitchen Consumer Products Company

“MCRI was the perfect fit for our major expansion. They provide first class service with the highest integrity. Their staff is very personable and was very successful in leading the engineering, procurement, and implementation phases of our material handling system needs.”

Plant Manager

International Paper

Motion Controls has been a Robotic Integrator of choice for our company for years. In our facility alone, they have perfectly executed 7 automation projects that have helped us become leaner and more efficient. They work very closely with us from the initial concept to the final implementation of the project. When we talk about Robotic automation for new projects we look no further than Motion Controls. I will give them 5 star rating.

Automotive Component Manufacturer

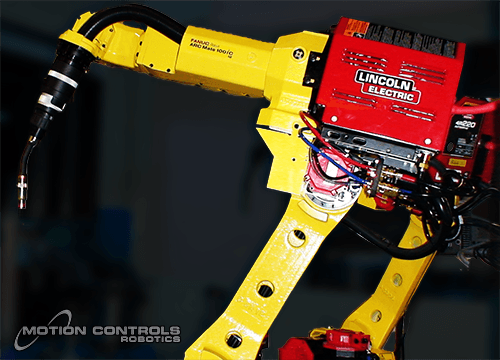

This is the eighth cell that we have purchased from Motion Controls and they are now the only vendor of robotic MIG cells at our plant. I’m sure that as we are growing we will continue to rely on them for new systems.

John Kachline

Welding Engineer

LuK USA LLC

“This system is duplicated on all of our assembly lines and will continue to be the standard for future assembly lines,” said LuK. “We had a very aggressive delivery schedule. This system had to be installed during the plant shutdown over the Christmas and New Year’s holiday. Motion Controls personnel put forth the extra effort to deliver the machine on time and get it up and running before our shutdown ended.”

LuK USA LLC

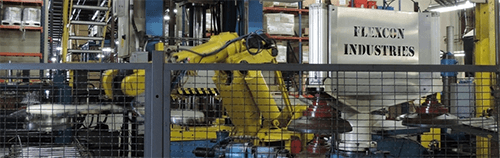

FLEXCON Industries

As far as integration goes, Motion Controls Robotics does a fantastic job. They were on target every time and never leave you hanging. The projects are on schedule, on budget and the engineering works right the first time or with minimal changes.

We would absolutely recommend integrating used robots. We never have a problem with the robot in the robotic cells. Motion Controls Robotics services the robot with a yearly preventative maintenance and we haven’t had a robot failure that caused us downtime.

Manufacturing Engineer

Flexcon Industries

Molded Plastic and Robotics Review

The project manager was obviously customer driven. The quality of his work along with his concentration of detail made this line a “showplace” within the Molded Plastics Division. Thank you for the work done here at Sonoco with the completion of the programming and training of our shortening container packaging line.

Sonoco Molded Plastics

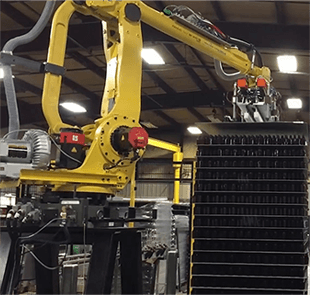

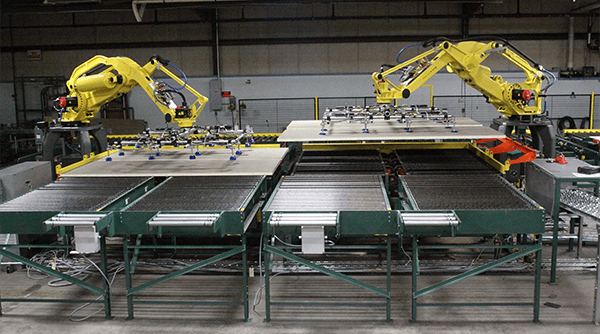

Robotic Board Handling System

The Motion Controls Board Handling System allowed us to increase production by 60 percent due to a faster run rate. Overall, we have seen an average of a 20% to 30% increase in production speeds.

The Motion Controls Board Handling System allowed us to increase production by 60 percent due to a faster run rate. Overall, we have seen an average of a 20% to 30% increase in production speeds.

Plant Manager

Robotic Material Handling Review

When we perform projects of this scale here at Bristol Firestone, we place a high value on working with competent contractors and vendors. Your company and employees that worked on this project go beyond competent. I am very impressed with the level of professionalism and quality of labor and equipment. Please thank all involved with this project. We look forward to working with your company and people in the future.

Firestone Building Products

Motion Controls has been a Robotic Integrator of choice for our company for years. In our facility alone, they have perfectly executed 7 automation projects that have helped us become leaner and more efficient. They work very closely with us from the initial concept to the final implementation of the project. When we talk about Robotic automation for new projects we look no further than Motion Controls. I will give them 5 star rating.

Motion Controls has been a Robotic Integrator of choice for our company for years. In our facility alone, they have perfectly executed 7 automation projects that have helped us become leaner and more efficient. They work very closely with us from the initial concept to the final implementation of the project. When we talk about Robotic automation for new projects we look no further than Motion Controls. I will give them 5 star rating.