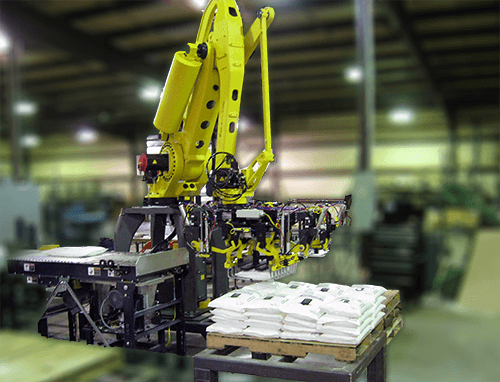

Bag Palletizing

Bag palletizing redefines your standards of operational efficiency and innovation.

Robotic bag palletizing will drive your end of line with a variety of benefits that elevate productivity, reduce operational costs, and enhance flexibility and precision in handling tasks.

Robotic Bag Palletizing is utilized by Food & Beverage, Consumer Goods, Medical, and Building and Construction industries to find more overall efficiency in both their manufacturing and distribution facilities.

Using robotics can:

- Save your employees from repetitive heavy lifting

- Improve product quality through inline checks and consistent handling

- Increase efficiency and productivity with consistent 24/7 operation

- Reduce the occurrence of unstable pallets through consistent stacking patterns

- Open up more flexibility and scalability in your process with systems that can handle a variety of sizes and weights

Easy to use

- Intuitive operation with pattern teaching

- Operator pendant for recipe adjustments and error reporting

- Fixed and flexible end of arm tools with proven designs

Increased throughput

- High reliability and uptime – 80,000+ hours mean time between failures

- High cycle rates up to 30 robot cycles per minute for case and bag handling

Reduced costs

- Labor savings

- Automated machine reduces worker compensation costs

- Reduced floor space requirements

Flexible and precise

- Handles various stack patterns

- PalletPRO™ software allows easy creation of new patterns as well as modifications to existing patterns

- Quick changeover using adjustable tooling and stored recipes

Programmable

- Built-in color operator pendant with stored recipes

- Recipe keeps part data such as product size and packing pattern, place locations and vacuum pattern

- Menu selection for pattern changeover

- On-the-fly process adjustments

Easy additions to your overall robotic bag palletizing system

- Automatic pallet dispensing

- Automated Vehicle Options for picking and moving full pallets

- Variable pattern placement programming

- Empty pallet transfer conveyors

- Slip sheet placement

- Automatic tier sheet insertion

- Full pallet transfer and accumulation conveyors

- Mixed load pallets

- Proven bag handling gripper allows fast cycle times as well as quick changeovers (Read more about Piab Bag Gripper)

- Multifunction end effectors that can handle pallet, bottom sheet, top sheet and top frame and no need to tool change

- Bottom trays

- Top trays

- Tool changers

- Wireless dressout increases reliability