What Could Be Easier Than Works-In-A-Drawer?

While visiting with a prospective customer recently the discussion got around to robot maintenance. One of our competitors had been selling the benefits of their maintenance/diagnostics software, so the customer was asking what FANUC robot maintenance had to offer in the way of diagnostics and maintenance support

For the record, FANUC has very powerful and capable maintenance software embedded in the base controller of each robot, has a deep level of on-line support documentation available for their robots, and has the best staffed 24/7 live robotics support network in North America.

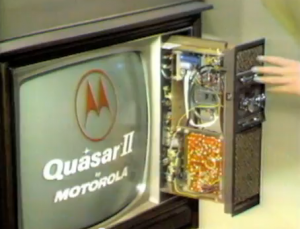

The discussion and the competitor’s sales pitch reminded me (I’m dating myself quite a bit here) of the old Motorola/Quasar advertising when color television was still in its infancy. Remember “Works in a Drawer”? Some time after Motorola began using transistors and printed circuit boards in place of vacuum tubes, they moved the printed circuit boards to the front of the television console, behind a panel face that tilted out to expose the boards. This made it easier for the TV repair man (or the TV’s owner if they had the nerve to go there) to adjust the tuning pots on the boards.

The discussion and the competitor’s sales pitch reminded me (I’m dating myself quite a bit here) of the old Motorola/Quasar advertising when color television was still in its infancy. Remember “Works in a Drawer”? Some time after Motorola began using transistors and printed circuit boards in place of vacuum tubes, they moved the printed circuit boards to the front of the television console, behind a panel face that tilted out to expose the boards. This made it easier for the TV repair man (or the TV’s owner if they had the nerve to go there) to adjust the tuning pots on the boards.

Quasar ran television and magazine ads proclaiming the new state of television; simpler and less expensive to maintain than ever! How could it get any easier than “…works in a drawer”! All you had to do was slide out the control panel, exposing those state of the art printed circuit boards to monkey with those tuning pots or, if things got really bad, to replace those boards. I don’t know for certain but I imagine there were troubleshooting instructions for the boards including color coded steps to make adjustments and do board replacement.

Can you imagine going to purchase a television or any other piece of electronics today and have the salesman give you a pitch on printed circuit board adjustment and replacement?

Yes, documentation for robotic controls is available, but that isn’t the point. The point is, at least for FANUC – the robot manufacturer we exclusively represent – the typical user doesn’t need to access the inner workings of their robot for maintenance purposes. Today’s robots are so reliable that average users cannot afford to stay current and trained in diagnostics and repair to servo motors, controllers, and mechanics of the robot itself. Training for robot maintenance and diagnostics is like learning a new software program; if you don’t use it, you lose it.

Yes, robots require annual preventative maintenance including greasing. And the owner (or a Certified Servicing Integrator like Motion Controls Robotics) is required to do preventive maintenance on the tooling and other equipment inside a robotic cell – items not part of the robot. But don’t worry about whether your FANUC robot maintenance information comes on a disk, in hard copy, from the internet, or any combination of these – because chances are, you won’t be using them.

If it’s yellow and it’s running, it must be from FANUC!

If it’s yellow and it’s running, it must be from FANUC!