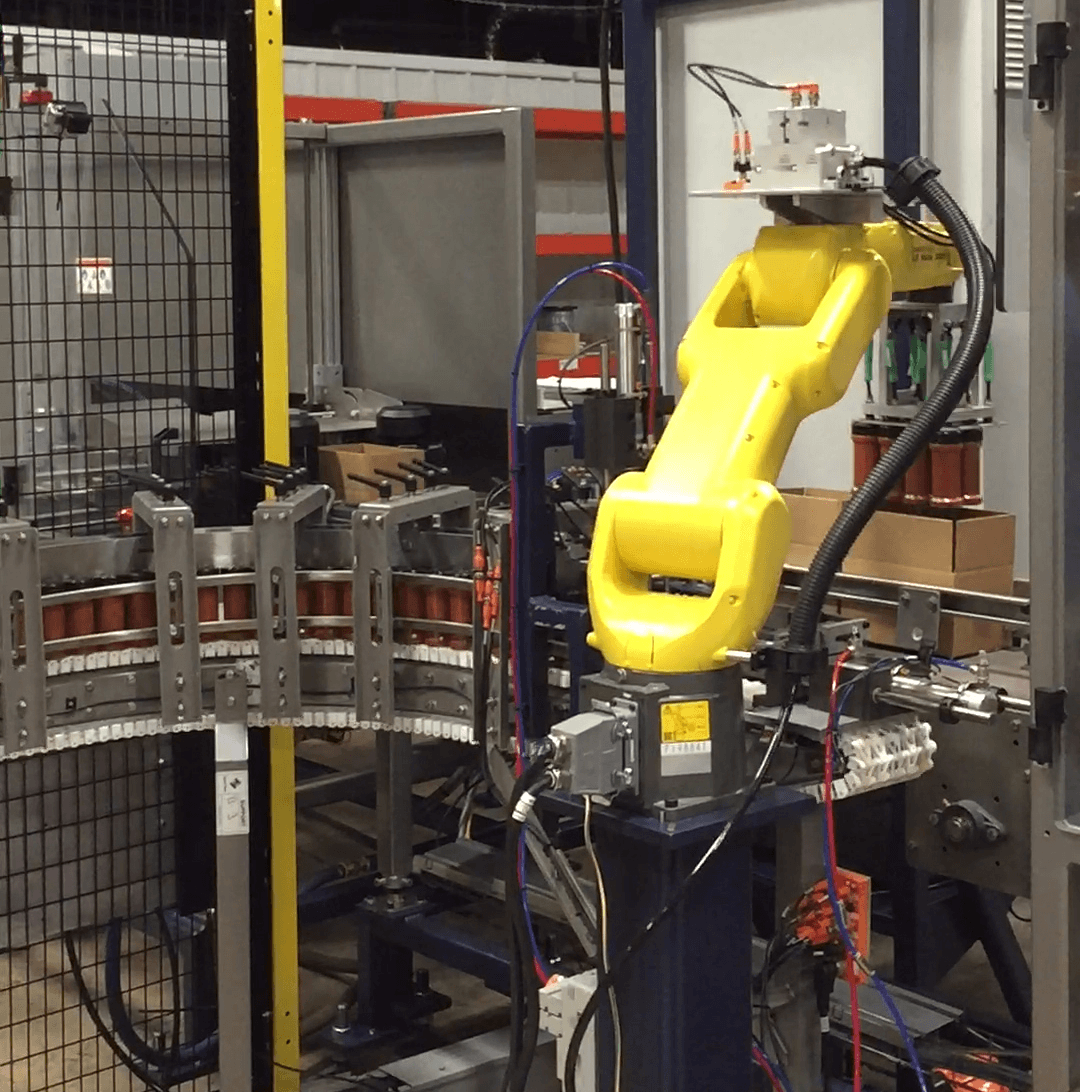

Bottle Case Packing

Motion Controls Robotics develops robotic bottle and container case packing systems that allow PET bottles and other containers to be automatically packed into pre-erected, lined or unlined corrugated cases.

- Bottles or other open top or closed containers are fed into the packing cell on flat top conveyor.

- Erected cases are placed on the case in-feed conveyor and are automatically registered for packing.

- If necessary, case flaps can be spread open to improve clearance into the case.

- Cases packed with bottles or containers exit the system for easy removal and if applicable, downstream robotic case palletizing.

The robotic bottle/container case packing system is flexible, precise, programmable and portable. The system reduces costs and is easy to use.

Full layer, or row bottle and container palletizing is also available from Motion Controls Robotics.

These systems reduce dunnage and packaging requirements. Manufacturers throughout North America are reducing their carbon footprint, improving their “green” status and reducing cost with this type of product palletizing.

Benefits

Easy To Use

- Portable units roll up to the end of an existing product conveyor

- Product may be stacked in upright, inverted and/or horizontal orientation using automatic tool changers

- Easy access door for change over adjustments

- Tooling is adjustable for a wide range of product sizes and pick positions

- Operator pendant for recipe management and error reporting

Reduced Cost

- Labor savings of up to two people per shift

- Automated machine reduces worker compensation costs

- Efficient floor space usage

Flexible and Precise

- Handles multiple product sizes

- Standard corrugated and plastic/film lined cases

- Precise, 6-axis servo-controlled system

- Accurate, reliable case counts

- Automatic tool change over

Programmable

- No need for direct teaching of points

- Built-in operator pendant with stored recipes

- Menu selection for patterns/pack outs

- Adjustable pick and place positions, on-the-fly

- Offline programming via easy-to-use text file – can be remotely reprogrammed by MCRI with local customer support if you wish

- 200+ part recipes keeps data such as part description, pick/place locations and stack patterns

Upgradeable

- Case in-feed conveyor can be attached to automated box erector

- Completed cases can be conveyed to automated case sealers for taping and downstream automated palletizing

Portable

- Case packer can be equipped with fork pockets or casters so it can be easily moved to any packaging line

- Interchangeable tooling between case packers