Software options, for FANUC robots, allow robots the flexibility to perform a variety of applications. Motion Controls Robotics focusses mainly on robotic material handling. Even if you narrow the scope to material handling, there are still over a hundred software options available. In a past article we discussed the software options almost all material handling applications will need (Read – Why do you need FANUC Robot Software Options). Here we count down the top 10 software options with a brief explanation and a few notes from our programmers.

Top Ten Software Options for Robotic Material Handling

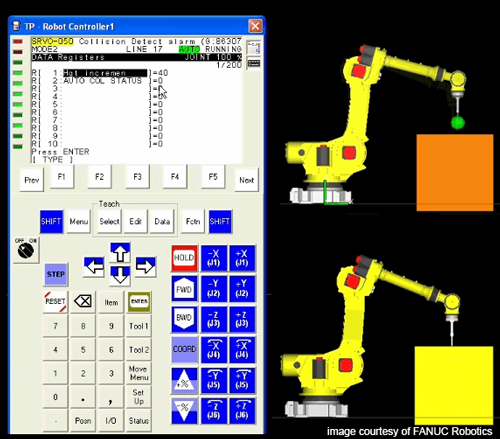

10. Collision Recovery (R791)

When a collision of any type occurs an alarm is raised, and the robot routine stops. This can cause delays in production especially if it is part of the normal procedure for small collisions to occur. So, Collision Recovery simply acknowledges the collision, resets, and continues.

MCRI is developing a system for picking a part using vision to locate the part. This option monitors the current on the desired servo of the robot, and if it exceeds a predetermined value the robot would know it “collided” with the part. This option allows the robot to stop prior to “faulting.” With this option, the robot automatically moves out of the way, a new picture is taken, robot re-positions, and then goes back to pick the part.

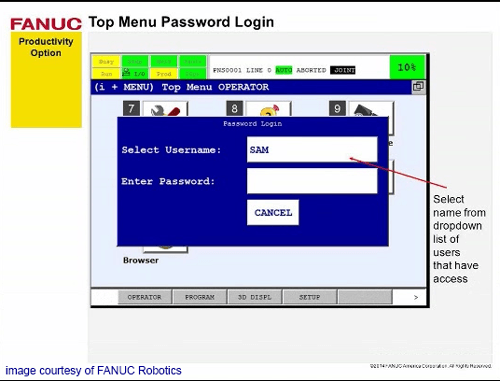

9. Password Protection (J541)

This option is utilized to password protect the programs and robot data. The user levels are highly customizable to a variety of access specifications/restrictions required.

MCRI has used Password Protection at the request of our customers to require a user login for HMI screen availability and to keep programming from being inadvertently modified by personnel at our customers’ facilities.

8. Ethernet I/P Scanner (R785)

When the robot is the main control of the system, this option allows the robot to communicate with other devices on the Ethernet I/P network.

Ethernet I/P Scanner is an option MCRI utilizes on systems that do not have PLC’s as the main control platform.

7. Motion Interface (R538)

Collecting diagnostic information about the robot and optimizing cycle times is possible with the use of this software options. This diagnostic information can be used to improve cycle times and the life of the mechanical unit reducers.

Packet contains 10 PDFs explaining each software option

6. Payload ID (J669)

This software option also helps with optimizing the robot’s potential for a longer life. Properly defining the payload at a variety of speeds improves accuracy and cycle time.

MCRI has over 20 years of experience programming robots and defining proper payloads. We can save our customers money on this option by using this experience to more precisely calculate payload data for the robot. But if you are not as familiar with FANUC robots, this software is very important.

5. Collision Guard (J684)

Collision Guard protects the system from potential collisions with objects by sensing changes in torque – the sensitivity to the change can be adjusted (increased or lowered). This software saves money by minimizing the damage to the robot and/or the End of Arm Tooling.

This option helps MCRI protect the robot from accidental collisions with structures, fixtures, and parts. Most importantly, the option is designed to allow the robot to “float” for a moment so that it can absorb the shock of a collision.

4. Ethernet I/P Adapter (R784)

This commonly used option allows ethernet communication between the robot and a Rockwell PLC with less complexity and cost.

MCRI uses this option frequently to communicate to the PLC for I/O and data exchange. This option gives us an I/O Network over Ethernet that is easy to setup and it is reliable.

3. Advanced Constant Path (R805 & R663)

Advanced Constant Path improves cycle time and the accuracy of product placement. One feature available through the software is the use of approach/retract linear distances to make sure the robot has an accurate path. Another way this option improves cycle time and placement accuracy is by using time before/time after option to turn on/off I/O before robot gets to position.

Advanced Constant Path is the most widely used option for MCRI. We utilize the features of this option to optimize cycle times and improve the longevity of the mechanical unit.

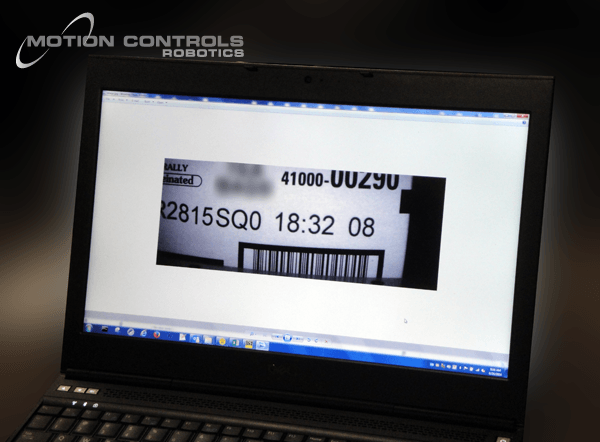

2. iRVision 2D Package (R685)

Vison in robotic systems is almost becoming a standard feature or want. iRVision 2D is used for product verification and reduces the need for outside fixtures to place/hold product.

This vision package option can help MCRI in inspecting parts, locating parts, and verifying parts are correct.

And the number one robotic material handling option is…

1. DCS Speed & Position Check Package (J567)

While some Dual Check Safety features are used to keep employees safe when working near or with robots, DCS also minimizes the workspace of the robot – decreasing total floorspace needed.

Almost all our robotic systems use DCS in one form to limit the robot’s motion. We also implement DCS Position Checks to help make homing the robot easier, since we can setup zones that let us know where the robot is at in the cell.

MCRI has over 20 years of experience programming robots and defining proper payloads. We can save our customers money on this option by using this experience to more precisely calculate payload data for the robot. But if you are not as familiar with FANUC robots, this software is very important.

MCRI has over 20 years of experience programming robots and defining proper payloads. We can save our customers money on this option by using this experience to more precisely calculate payload data for the robot. But if you are not as familiar with FANUC robots, this software is very important.