There are now three series of Collaborative Robots available from FANUC. MCRI can help you select the collaborative robot that is best for your application, but you can start your search by going through the cobot options offered and see the specific benefits for each series.

All three series are designed to work alongside operators in a process to add:

- Speed – Add a robot to help complete a task. The cobot removes the wasted time of moving back and forth in the cell.

- Quality – A collaborative robot can perform regular quality checks using vision, scales, a part tester, and more.

- Flexibility – Move the robot around the facility when demand changes for certain products.

- Safety – Have the robot do the heavy, dirty, or hot/cold jobs.

Cobot Options

All versions of FANUC collaborative robots are built to last in industrial environments.

Compact Collaborative Robots – reliable, durable, and flexible

There are 4 models in the compact series. These cobots can handle up to 14kg/30lbs and have an IP 67 rating. With the higher IP rating, if you have a more demanding or harsh environment, this series is your best selection.

Higher Payload Collaborative Robots – reliable, strong, and flexible

The options for the higher payload collaborative allow operators to work along side a robot and have the robot do the heavy lifting. With the ability to lift up to 35kg/77kg, it saves on repetitive motion injuries. These options are also great for palletizing applications.

CRX Series Collaborative Robot – reliable, easy to program, and flexible

These 10kg/22lbs payload robots march into the lineup summer 2020. They are a completely new offering from FANUC bring a more lightweight option (not light payload but the robot is a lot lighter weighing in at about 40kg/88lbs). The CRX can easily be moved around the facility to do different jobs and installed at any angle to make it more flexible. The main benefit of these robots is, while they still run on the same FANUC platform, they are even easier to program even for beginners, quick to setup, and can be run from a tablet program instead of requiring the need for a teach pendant.

Some of the Other New Features of the CRX Series

- The CRX series have torque sensors in each joint instead of the dual channel force sensor at the base.

- Under-flip motion – the offset wrist allows for an under-flip motion. This unique, time saving move can reduce cycle time by 15-25%.

- Any collaborative gripper currently on market is usable and FANUC has extra bolt holes for even better rigidity.

- Air for the gripper is routed externally with dress packages.

- The CRX has an IP54 rating when installed in a vertical position and IP20 rated when installed horizontally.

You can see a quick list of all these robot models on this collaborative robot chart

The 3 Ps of Collaborative Robots

Power & Force Limited

One thing to always keep in mind about collaborative robots is when they are working alongside a human they do not operate as fast as conventional robots. The speed must ensure the robot movement can stop quickly and only exert <33.5 pounds of pressure if the operator moves into the path. All the cobots can run at a faster speed if they are not working alongside an operator. For example, you keep the CR running after hours to finish packing, palletizing, assembly, or machining projects to increase rate or meet demand. The speed model for the robots are collaborative mode speed is 1,000 mm/sec and contact stop disabled speed is 2,000 mm/sec.

Programming is Quick & Easy

Programming differs in the new CRX series robots and the green line of collaborative. Both cobots have the ability for hand guidance for point programming, but the new CRX series uses a simplified interface. The CRX are run from a tablet instead of a teach pendent. This brings flexibility to the software application’s power and ease of use. This platform includes drag and drop, inference options, and points programming.

The tablet teach pendants used with the CRX series are wired and have an emergency stop button to meet safety requirements.

Portability & Flexibility of Application

One of the main benefits of adding a collaborative robot to your facility is the flexibility for it to fill gaps in manufacturing needs. All but one of the collaborative robots can be made easily portable to move around the facility. The collaborative series can be added to a cart and the CRX series is lightweight enough at 40kg/88lbs for a couple of people to it pick up. The CRX controller (R-30iB Mini Plus Controller) has a convenient carry handle and are under 20kg. All the portable models can be ordered to use a standard wall outlet. This makes it easy to just roll the robot up to the application and start working.

An added portability & flexibility to the CRX is the ease of changeover and amount of options for end of arm tooling from a variety of third-party suppliers:

- Schmalz – vacuum pads

- Robotiq – mechanical grippers

- Schunk – mechanical grippers

- Soft Robotics – mechanical grippers

- Piab -Simple vacuum cup for picking

Green Collaborative mode – contact stop enabled

Yellow- high speed mode – contact stop disabled through a safety related device

Red – Faulted

Cobot Options for Applications

Collaborative robots can do almost any application that fits in the weight class available.

Cobot Picking & Packing

Collaborative robots for picking/packing applications allow flexibility for your facility. Having a collaborative station available to move around to different locations gives you choices when employees call-in sick or you need to meet higher rates. Tasks such as product weighing, bin picking, kitting, and product testing can all be done along-side an operator.

Cobot Palletizing Options or Depalletizing

While Cobot palletizing options are unlimited, the palletizing rate of a collaborative will be lower than non-collaborative FANUC robots. Collaborative robots are well suited for high mix, low volume product flow. The same is true for depalletizing. Add a 3D area scanner and a collaborative robot can help to unpack mixed pallets.

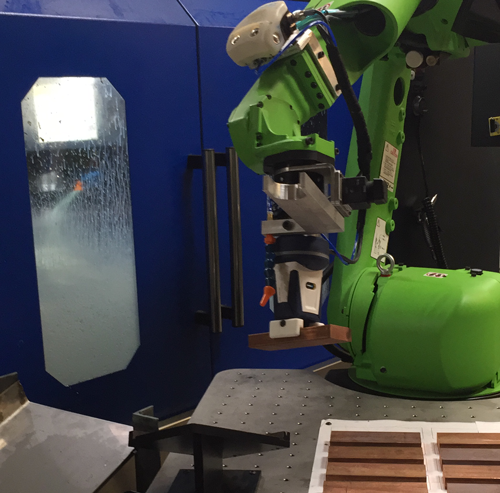

Machine Load/Unload

Need a certain part for an assembly project done for the next day, this is the perfect job for a collaborative robot. Roll up the robot to the CNC and let it work all night. The parts will be ready by morning.

Product Testing & Assembly

Add a collaborative robot to the assembly line for part assembly or testing. When you have a multi-step assembly process, a collaborative robot can takeover a few steps to allow the operator/assembler to focus on the final product.

If you have an application or process where you would like to explore adding a collaborative robot, contact MCRI and we can discuss your options.