What automation topics were the most researched on the Motion Controls Robotics website?

10. Industry Information

Our site invites industries to focus on what we can do specifically for them, and many users take advantage of this by finding their industry page – Food and Beverage, Building and Construction, Plastics and Containers, Components, Converting and Packaging, and Fulfilment and Distribution.

9. End of Arm Tooling

Connecting to our number one most popular topic, end of arm tooling can be another complicated step in deciding how to build the perfect robot system for your process. We like to make sure customers have all the information about the options available because, while we are experts in robotics, you are the expert in your product. Our EOAT series is helpful when starting to think about your robot system.

8. Case Packing

Case packing is one of our most popular applications, especially in the consumer goods industries. Vision technologies have given manufacturers so many new options for quality and flexibility for packing products. One example is shown in an article about case completeness – adding this to the case packing process ensures quality and minimizes loss of product. Visitors to the site are also very interested in seeing what options are available for case erecting.

7. Picking and Labeling

Logistics companies are seeing how high-speed robots, like SCARAs and Deltas, can be used for high tech labeling applications. Labeling products is an added value to any robot system where accurately tracking product is important.

6. Roll Handling

We have many customers in the converting industry and have developed a variety of applications to improve these processes. Companies searching to improve their process are reading about palletizing, packing and labeling. Each year we attend the two Converters Expos to keep up-to-date with the industry needs.

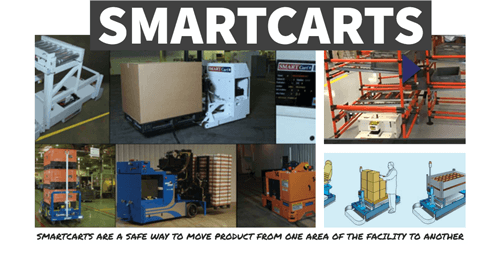

5. Automatic Guided Cars and Vehicles

SmartCarts are being used in conjunction with robotics to build very consistent and predictable processes. Using carts as service robots to bring and remove product at a specific rate means you will not miss those order deadlines. Users on our site like to learn about the different AGVs and AGCs available and what they can do to improve your throughput and competitive advantage.

Users on our site like to learn about the different AGVs and AGCs available and what they can do to improve your throughput and competitive advantage.

4. Safety

According to Automation World, safety is at the top of many manufacturers minds when adding robotics. For one, improving employee safety by removing repetitive motion injuries, heavy lifting dangers, and chemical or heat exposure issues. But moreover, the popularity of robotics has led to many new startups building robot systems without the knowledge of the proper safety aspects. Educating people looking for robot systems about safety is a top priority for us, and we have a series of articles that review safe robot system practices.

3. Robotic Palletizing

To stay competitive, as companies grow, the first thing often looked at is adding an end-of-line solution like palletizing. Robotics makes palletizing flexible and reliable. A quarter of all the systems we build include palletizing as part of the overall system. The flexibility of palletizing options has improved so much, last year we developed a system that could palletize large barrels and small cases in the same space at the same time.

2. Engineering\Programming

So, it goes to say that the other big user group of our website are people that have already purchased or are working with robotics. We developed a How-to Robot series of videos that explain the main tasks most operators will encounter working with a robot system. These have been a big hit, and we love to hear about any topics that might make robot operators more prepared.

1. Robots

No, you say! This is probably a good place to start when exploring robotics. This category includes FANUC robot model information, pricing, robot software, and tips for selecting the best robot for your application. The top of the list is our range of robot cots series and the new robot catalog.

Thank you to all of our readers for a great 2018- we want to continue to answer all your robot questions, so please send any article ideas to us. Here is to a great 2019!