Robotic Random Bin Picking

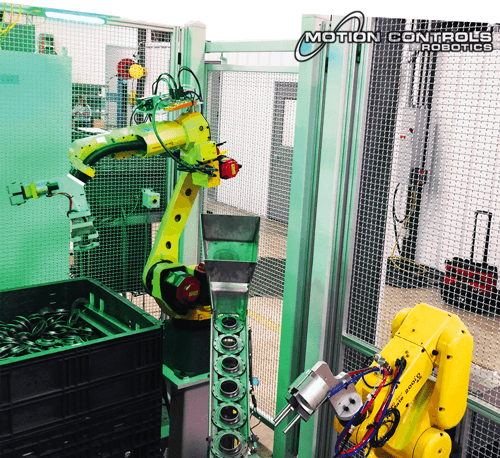

Robotic random bin picking is a process used for machine loading and/or separating parts from a bin for production purposes. This process is commonly seen in industries dealing with automotive stampings, molded plastics, or medical assemblies. When deciding on developing a robotic bin picking cell, the part to be picked has to be analyzed based on its shape, material and size. Then the cycle time for picking and placing these parts needs to be considered. Typically the rate for picking parts from a bin ranges from 6-15 parts per minute. Bins containing randomly placed parts can be large wire containers, a small to large plastic tote, or even a tray.

Flexible end of arm tools and 3D vision systems are used to accommodate a variety of bin setups:

- Dealing with part size, shape, and weight

- Removing tier sheets that separate part layers

- Dealing with tall bins that need emptied

- Discovering pick patterns for parts that are placed in a bin randomly

- Quality controls on parts that do not match specifications

- Accuracy of final part placement

Benefits

Easy to use

- Can be used with a variety of part sizes, shapes, and materials

Increased throughput

- Cycle time using bin picking ranges from 4-10 seconds per pick

- System can warn when bin is getting close to being empty so it can be replaced in a timely manner

Reduce costs and improve safety

- ROI for bin picking projects can be 6 months to 2 years, depending on cost of labor, number of shifts of operation, and ancillary operations that can be incorporated into the bin picking operation

- Reduces later quality issues by identifying parts that do not meet specifications

- Having robots reach into bins to remove heavy parts helps eliminate repetitive motion and reduces injuries to employees.

Flexible and precise

- Vision locates bin placement and dimensions to avoid collisions between robot and bin

- Multi-gripper can be used that combines vacuum, mechanical, and/or magnetic grippers based on part and other process needs

- Offers more flexibility than hard automation part feeding systems like bowl feeders, as part designs change

- Accurately orients part after pick for final placement

Programmable

- Vision Guided Robotics – 3DAS (3D Area Scanner) creates a point cloud map of the parts in the bin, improving picking through-put

- Uses on-the-fly vision scanning to reduce missed picks, and in some cases determine part orientation

- A variety of qualified parts can be programmed to be picked using same robot

Bin Picking Video

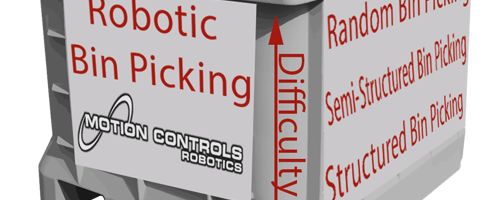

Random vs. Structured Bin Picking

In the above image you can see some parts are placed randomly in the bin while some are organized either with or without dividers.

- Structured bin picking has parts in specific locations, ordered. This type of bin picking is typically simpler and less expensive to execute at the unload end of the manufacturing operation.

- Random bin picking satisfies ultimate material handling objectives; bulk fill containers with parts coming directly off of manufacturing cell. Transport bin to downstream operation, set the bin in place, and automated manufacturing can resume.