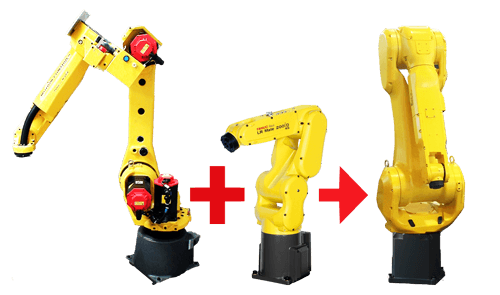

The M20iB/25 got a makeover that crossed the performance and capabilities of the LR Mate and the M20iA. This new model offers increased:

- payload from 20 kg to 25kg

- work envelope and reach from 1812 mm to 1853 mm

- average speed on all axes (21%)

- repeatability to +/-.06mm because of the new more rigid design

- cycles per minute (CPM) from 76 to 80 at 1 kg

The M20iB/25 has enclosed, integrated cables, motors, and arm so it receives a IP67 rating on all six axes. This rating makes the robot perfect for working in special environments these might include food handling, wet, dirty and harsh processes.

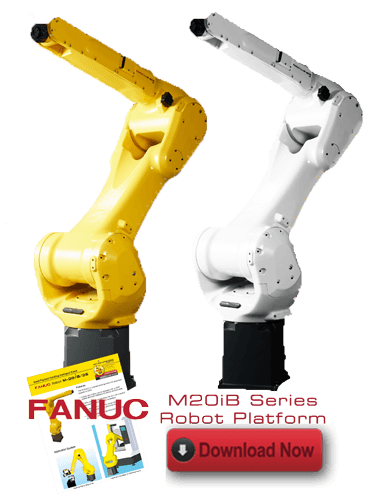

The newest version of the M20iB/25 is a white food grade or clean room robot. This version of the series will come out before the end of the year (2016). The food grade model will have all of the same specifications.

In addition the M20iB offers

- slim upper arm that prevents interference with peripheral devices

- strong wrist

- rear or bottom cable exit

Robot Applications

The M20iB applications include packaging and machine load/unload. iRVision and other intelligent technologies can be integrated into the system.

If you have an application that would benefit from this robot’s increased precision and repeatability, contact us using our robot request form.