This facility is the perfect place to take a robot tour and learn all the ways FANUC robots can transform your manufacturing process.

More Robots in Stock

This warehouse area will shrink the lead time for integrators to get a FANUC robot in-house to start developing a customer’s project. Some pipeline robots will be available in as little as 2-3 weeks. When in full swing, the center will house a total of 2500 robots, increasing their current inventory by 107%. This inventory will consist of a variety of models (reach/payload) for each robot series.

Application Testing

Centerpointe Technology Center also has special robot and end of arm tooling testing spots. These areas allow a manufacturer to test an application for efficiency and speed. The robot will repeat a specific process with a load on the end of arm tool and analyze the results over a given number of cycles.

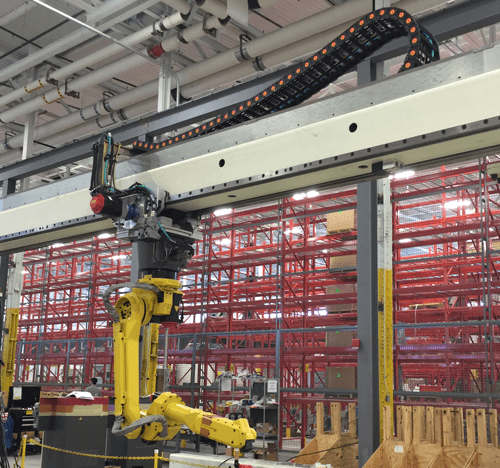

The Part Warehouse at Centerpointe Technology Center

Just under half of the facility is dedicated to a logistics area. The logistics area has floor to ceiling shelving to store replacement parts. These replacement parts speed delivery to customers – bringing the FANUC Service First promise to the forefront of their priority for customer service and reliability.

The shelving in the warehouse area is color-coded and all parts and shelving locations are kept in a global parts database. Conveniently located near the parts storage area is a group of stations/workcenters for part and robot refurbishing. This area also helps FANUC keep customers’ robots reliable and durable for the life of the robot.

sensor system