Robot System Cost Series

Part Two: The Range of Robot Cost

Part Three: A Cost Analysis of a Palletizing System

Your team needs to discuss the questions listed in this first article before contacting an integrator for a robot system cost.

How Much Does a Robot System Cost?

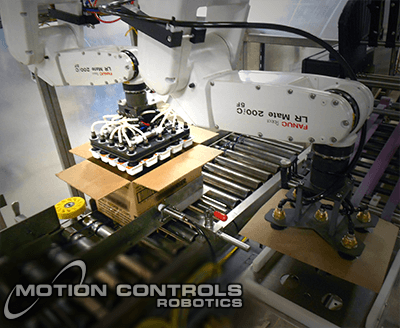

As you might expect, with Motion Controls Robotics being a Certified Servicing Integrator for FANUC Robotics, we hear this question nearly every day.

A robot integrator must consider multiple parameters when addressing the question of robot system cost:

- What is your timeline?

- Are we replacing an existing operation (exactly or very similar) or is this a new process?

- Has a solution been developed for your project by MCRI or another integrator?

- Will we be breaking new ground?

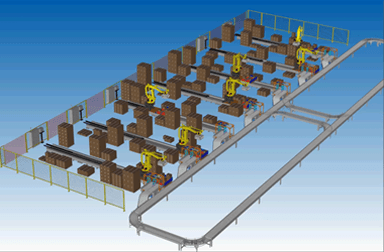

Are you confident you know how many robots will be required for your project? If not, one way to gain that confidence is to have one or more integrators perform a simulation for you that models the robot(s) handling your product at your required rate(s). FANUC makes Roboguide available to its integrators that allows real time, highly accurate simulations with software that exactly mimics the kinematics of FANUC robots carrying your specified load. FANUC Certified Servicing Integrators can model the inertias and payloads for your application, along with estimates of same for end of arm tooling, to determine exactly how the robot will perform in your application including robot reach details.

Are you confident you know how many robots will be required for your project? If not, one way to gain that confidence is to have one or more integrators perform a simulation for you that models the robot(s) handling your product at your required rate(s). FANUC makes Roboguide available to its integrators that allows real time, highly accurate simulations with software that exactly mimics the kinematics of FANUC robots carrying your specified load. FANUC Certified Servicing Integrators can model the inertias and payloads for your application, along with estimates of same for end of arm tooling, to determine exactly how the robot will perform in your application including robot reach details.- Do you have project requirements defined and organized? These may include but are not limited to:

- case and pallet sizes

- pallet patterns and related dunnage requirements

- rates

- hours of operation

- Do you have any non-standard packaging or palletizing requirements? Some examples would be:

- a need for corner boards

- tray packaging

- ensuring labels out on all outside cases of a pallet pattern

- need to double stack pallets

- Is there a project layout to work from or do you need help to develop a concept and a drawing?

- Do you have special plant or process requirements such as:

- a non-standard control system architecture

- special maintenance functions

- clean room

- hazardous or corrosive environment

- What level of participation do you plan to have in the project (e.g. it isn’t uncommon for customers to want to install equipment with their own maintenance personnel or supply some of their own equipment)?

- Are there major system components required that an integrator may not manufacture themselves, and what level of responsibility do you want the integrator to have for those items? Some examples are:

- stretchwrappers

- strappers

- bar code reading system

- label printing and applying or bar code scanning equipment

- special packaging machinery

- case or pallet conveyor

- Will a standard model robot do the job for the application or will a special model, higher cost robot be required:

- Food grade model

- long arm variation

- wash down variation

- high capacity variation

These 10 considerations are just the beginning in figuring out how much your total robot system will cost. Next you can dive into the cost of the robot and how features effect price.

Robot System Cost Questions

We have provided a fill-able form for you to download. Furthermore, use this questionnaire when preparing to contact an integrator for a quote. This form, which includes the above questions, will allow you to respond quickly to what any robotic integrator will need to know about your project.

Contact Motion Controls Robotics today if you would like to get started with your robot system quote.