While FANUC has a full line of industrial robots (payloads range from .5kg to 2300kg), below are the collaborative models that have been developed for applications required by robotic customers.

FANUC Collaborative Robots Available Through MCRI

See the 3 P’s of Collaborative Robots

| Robot/Description | Specifications |

|---|---|

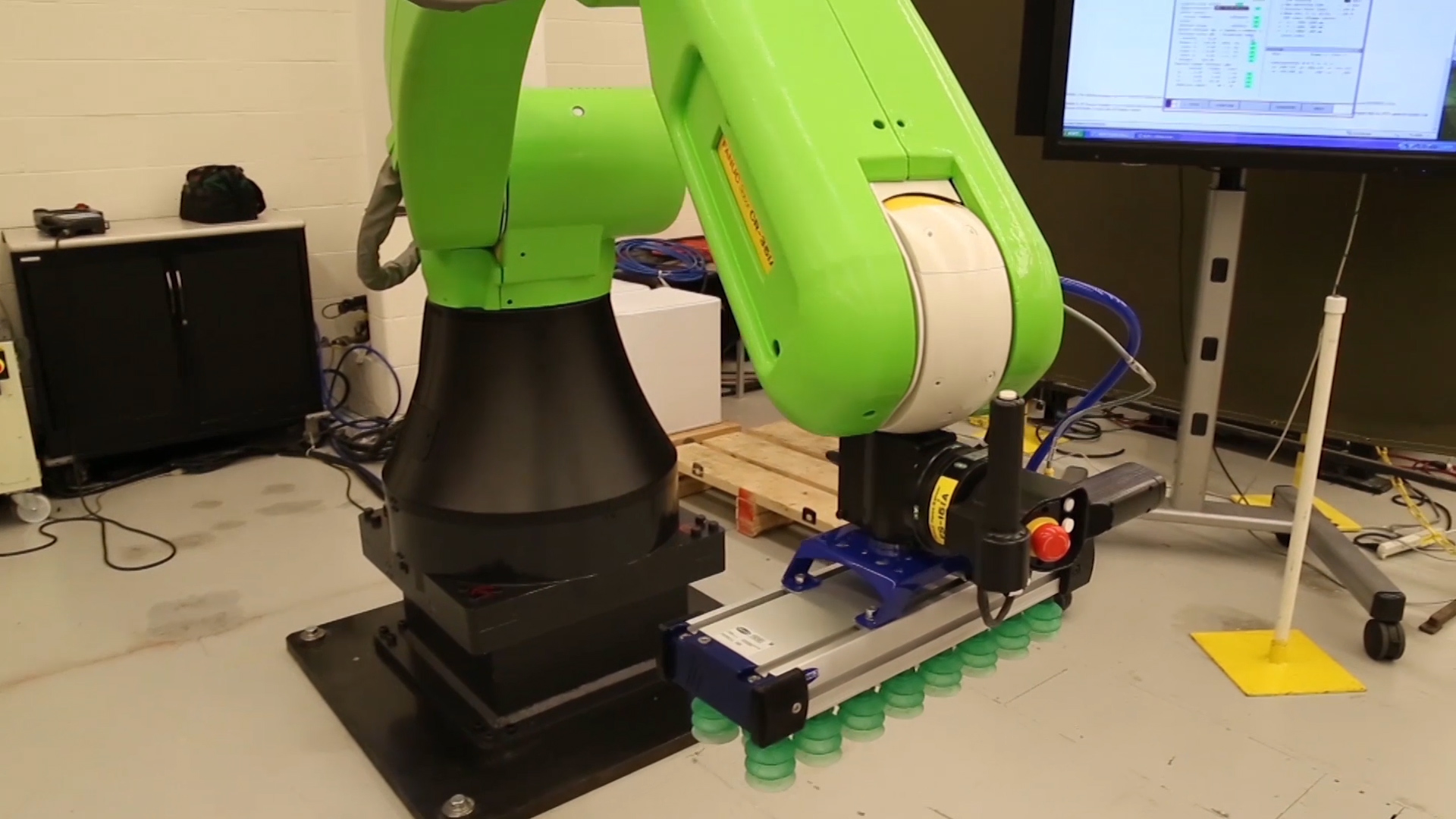

CR-35iA – First collaborative robot to be able to lift up to 35kg (77 pounds) and work alongside humans without safety fencing. The CR-35iA can be installed on the floor only. CR-35iA – First collaborative robot to be able to lift up to 35kg (77 pounds) and work alongside humans without safety fencing. The CR-35iA can be installed on the floor only.Visit CR-35iA Product Page |

Payload: 35 kg / 77 lbs

Reach: 1813 mm / 71 in |

CR-15iA – Collaborative robot designed for picking and sorting using the sleek, yet longer reach capabilities of the base M-10 robot model. The CR-15iA can be installed on the floor, wall, or ceiling. CR-15iA – Collaborative robot designed for picking and sorting using the sleek, yet longer reach capabilities of the base M-10 robot model. The CR-15iA can be installed on the floor, wall, or ceiling.Visit CR-15iA Product Page |

Payload: 15 kg / 33 lbs

Reach: 1,441mm / 57 in |

CR-4iA – This smallest payload option is perfect for tabletop applications for assembly or part handling. The CR-4iA can be installed on the floor, wall, or ceiling. CR-4iA – This smallest payload option is perfect for tabletop applications for assembly or part handling. The CR-4iA can be installed on the floor, wall, or ceiling.Visit CR-4iA Product Page |

Payload: 4 kg / 77 lbs

Reach: 550 mm / 21 in |

CR-7iA – Allows for more flexibility in installation options. Developed for use in applications with lighter part lifting, part sorting, and assembly. The CR-7iA can be installed on the floor, wall, or ceiling. CR-7iA – Allows for more flexibility in installation options. Developed for use in applications with lighter part lifting, part sorting, and assembly. The CR-7iA can be installed on the floor, wall, or ceiling.Visit CR-7iA Product Page |

Payload: 7 kg / 15 lbs

Reach: 717 mm / 28 in |

CR-7iAL – This is the long arm version for extended reach capability giving the customer the perfect robot for their application. The CR-7iAL can be installed on the floor, wall, or ceiling. CR-7iAL – This is the long arm version for extended reach capability giving the customer the perfect robot for their application. The CR-7iAL can be installed on the floor, wall, or ceiling.Visit CR-7iAL Product Page |

Payload: 7 kg / 15 lbs

Reach: 911 mm / 36 in |

CRX-5iA – This compact and lightweight robot can be added to a manual or automated cart to pick and place product for wall sortation, kitting, and other small payload piece picking. CRX-5iA – This compact and lightweight robot can be added to a manual or automated cart to pick and place product for wall sortation, kitting, and other small payload piece picking.Visit CRX-5iA Product Page |

Payload: 5 kg / 11 lbs

Reach: 994 mm / 39 in |

CRX-10iA – This lightweight, reliable collaborative robot comes with the R-30iB Mini Plus Controller. This robot has very versatile mounting options for palletizing, case packing, assembly, and load/unload applications. CRX-10iA – This lightweight, reliable collaborative robot comes with the R-30iB Mini Plus Controller. This robot has very versatile mounting options for palletizing, case packing, assembly, and load/unload applications.Visit CRX-10iA Product Page |

Payload:10k g /22 lbs

Reach: 1249 mm / 49 in |

CRX-10iA/L – This is the long arm version of the CR-7iA for extended reach capability. This robot has versatile mounting options for palletizing, case packing, assembly, and load/unload applications. CRX-10iA/L – This is the long arm version of the CR-7iA for extended reach capability. This robot has versatile mounting options for palletizing, case packing, assembly, and load/unload applications.Visit CRX-10iA/L Product Page |

Payload: 10 kg / 22 lbs

Reach: 1418 mm / 55 in |

CRX-20iA/L – This is a long arm model for increased reach capability. Great options for mobility with carts and lifts. This robot has versatile mounting options for robotic wall sortation, case packing, assembly, and kitting applications. CRX-20iA/L – This is a long arm model for increased reach capability. Great options for mobility with carts and lifts. This robot has versatile mounting options for robotic wall sortation, case packing, assembly, and kitting applications.Visit CRX-20iA/L Product Page |

Payload: 20 kg / 44 lbs

Reach: 1418 mm / 55 in |

CRX-25iA – The CRX-25 was built as a collaborative palletizing robot. The long reach and higher payload give the palletizer a wider range of flexibility for case size and weight. CRX-25iA – The CRX-25 was built as a collaborative palletizing robot. The long reach and higher payload give the palletizer a wider range of flexibility for case size and weight.Visit CRX-25iA Product Page |

Payload: 25 kg / 55 lbs

Reach: 1889 mm / 74 in |

Selecting the Best Collaborative Robot

Trying to design a robotic application where the operator and robot need to work in the same space? The top 2 decisions when selecting the best collaborative robot are:

- How closely do the operator and robot need to work together?

- What brand of collaborative robot should we select?

How closely do the operator and robot need to work together?

Collaborative operations are defined in ISO 10218, ISO/TS 15066 based on four levels of safety. FANUC has developed hardware and software solutions for each type of operation.

- Safety-rated monitored stop – the robot is stopped when operator is in the robot zone.

- Hand guiding – read more

- Speed and separation monitoring – robot and operator can work in the same area, but speed of the robot is controlled by zones. This means as the operator approaches, the robot slows, and as the operator enters the robot space, the robot stops. Read more

- Power and force limiting – The robot and operator work and interact in the same space. The robot is specially designated to work collaboratively, and the robot speed is adjusted and force is limited to the ISO standards for under 210N.

From the four collaborative descriptions above, only one actually requires a collaborative robot. So, it is important when looking at your application you only select a collaborative robot when the operator must actually interact with the robot. Otherwise, there are safety solutions that can be put in place allowing different levels of collaboration.

What brand of collaborative robot should we select?

There are a variety of collaborative robot companies and robot options. FANUC robotics is the leading supplier of industrial robots with almost 60 years’ experience. Based on this resume, taking a look at FANUC’s collaborative options, to see if they have the best collaborative robot, is a must.

The Main Benefits of Selecting a FANUC Collaborative Robot Model

- FANUC’s collaborative options offer a high degree of functionality and durability at a small cost difference over other available brands.

- FANUC offers a full line of robots for your industry – meaning you can have one robot hardware and programming platform for your entire facility, handling everything from smallest to largest load, easiest to most challenging cycle time/duty cycle, and both collaborative as well as non-collaborative robot options.

- FANUC’s collaborative robots are under the Service First guarantee from not only FANUC, but FANUC authorized integrators who have years of robotic automation integration experience. Other collaborative robot brands are sold through power and controls hardware suppliers with limited robotic integration experience. FANUC also supports all robots for the life of production.

- All FANUC robots come hardware ready for integrated FANUC iRVision and force sensing capabilities.

- FANUC’s Dual Check Safety (DCS) software provides very high granularity and the ability to create complex shapes for safe zones around the robot arm and in the robot workspace, not just simple Cartesian planes and block zones.

- I/O signals, integrated valves, and air can be run inside the FANUC CR35 and LR Mate collaborative robot arms for simpler, cleaner end of arm tool dressout.

- FANUC’s collaborative robots offer, more complete connectivity to external safety devices such as Devicenet, Ethernet/IP Safe, etc.

- FANUC collaborative options are very extremely accurate and repeatable within the full operating range and capacity of each robot ( .02mm repeatability on LR Mate CR-4iA, .03mm on CR-7iA).

- There is a special CRX website for training options – CRX e-Learning.

If you are exploring adding a collaborative application in your facility, we would love to help answer questions you may have. Or, using the button below, you can start exploring applications and systems MCRI has developed using FANUC robots.

If you are exploring adding a collaborative application in your facility, we would love to help answer questions you may have. Or, using the button below, you can start exploring applications and systems MCRI has developed using FANUC robots.