Robotic Roll Handling

Heavy to small rolls | Labeling | Palletizing | Robot teamwork

Our robotic roll handling solutions are here to help you find efficiency, precision, and safety in your processes. In the competitive manufacturing world, the need for streamlined and cost-effective roll handling is greater than ever. With our automation options, you can transform the way you handle rolls of all:

- sizes

- materials

- weights.

Relieve your valuable employees of heavy lifting, repetitive tasks, and workplace injuries. Our robotic roll handling systems are designed to optimize your operations, reduce downtime, and boost productivity

The videos and information below show the benefits of robotic roll handling, from increased efficiency and accuracy to improved workplace safety. Discover how our solutions can meet your unique needs, no matter the industry or application.

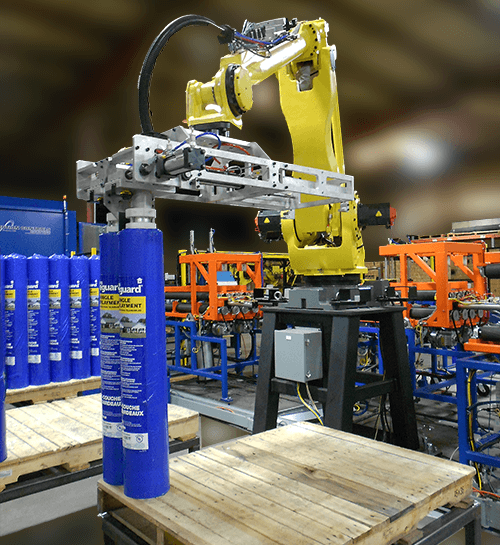

Examples of Roll Handling Systems

Large to Small Rolls

Handling Small Rolls of Blown Film - Case Erecting-Picking-Packing-Labeling-Palletizing

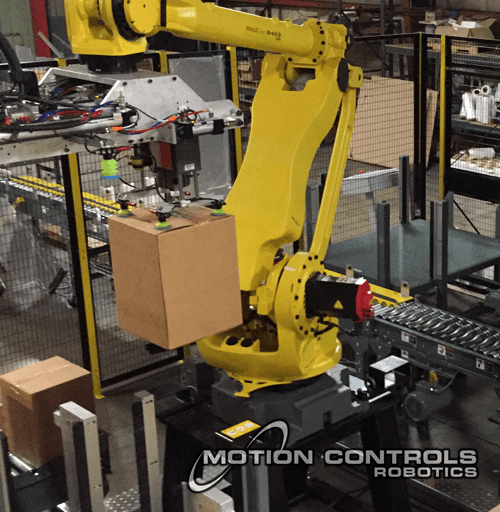

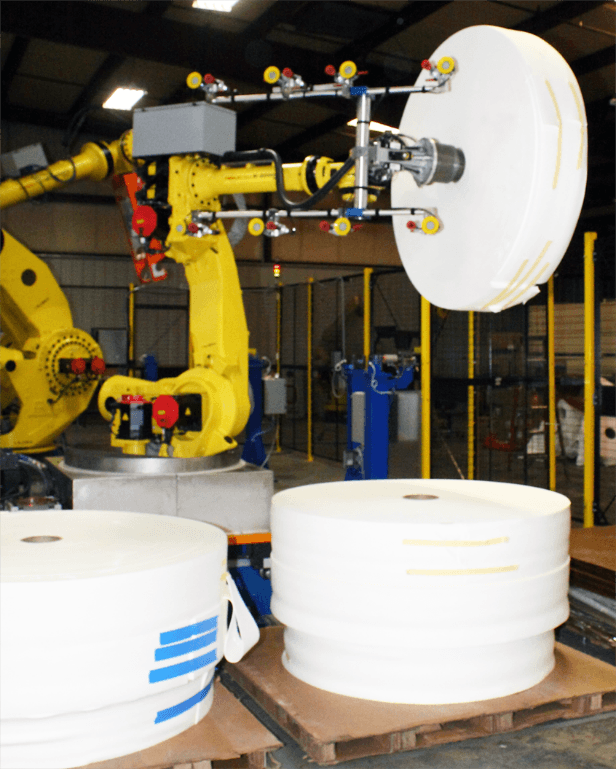

Motion Controls Robotics has designed a variety of robotic roll handling systems, including palletizing, packaging, machine tending, and general roll/material handling.

We can design your robot cell with future needs in mind, so your robots are reusable and re-deployable if

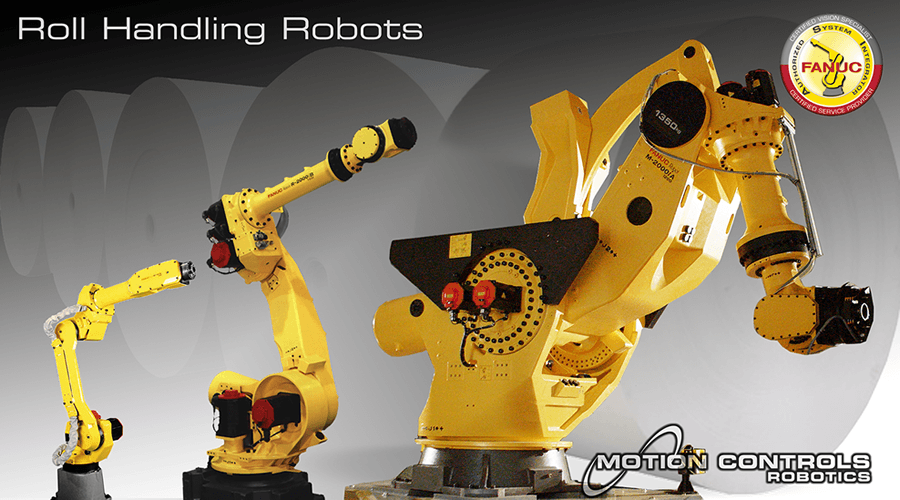

there are product changes. Six axis robots are typically selected for roll handling applications – below are commonly used roll handling robots. Click on the robot to learn more.

Benefits for Robotic Roll Handling

Easy To Use

- Servo operated robot end of arm tool can be programmed to grab a wide range of roll diameters

- Easy access door(s) for change over adjustments

- Operator pendant or HMI screen for recipe management and error reporting

Reduced Costs

- Fully automatic operation eliminates all related palletizing/packaging labor

- Automated machine reduces worker compensation costs

- Efficient floor space usage

Flexible and Precise

- Handles multiple product sizes

- Flexible end packaging

- Precise, 6-axis servo-controlled system

Programmable

- Simple HMI screen(s) or operator pendant with stored recipes

Upgradeable

- Upstream and downstream operations can be added to the robotic work cell in the future