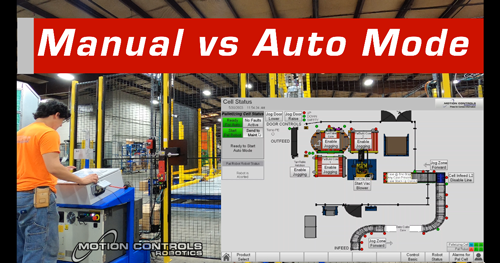

Levels of System Automation

The levels of system automation that you implement in your facility can range from single small cells to large interconnected systems. The great thing is the ability to start small and grow when you want to find more automation benefits.…